Process

TCS Operation

The TCS operation sequence begins by purging the entire system with fresh air. After purge, the TCS pilot and main burners are ignited and held in place until appropriate flame scanning safeties are met. Once flame safety requirements are met, process gas may be introduced to the TCS. The TCS system will automatically adjust to different volumes, concentrations, and heat values of the process gas. If the process gas does not have the energy to support combustion, natural gas may be added as a support fuel.

The introduction of process gas will increase the internal temperature within the combustion chamber. To control the temperature and facilitate combustion fresh air is added to the system. The fresh air can be naturally aspirated or forced into the system. The combustion air brought into the system ensures mixing, sufficient oxygen, and controlled temperature combustion providing the optimum VOC destruction efficiency

Features

All Thermal Combustor Systems are fully enclosed flare designs that hide the flame while thermally combusting the vapor gas steam. This supports a safe design when compared to exposed flame flare systems and allows installation in numerous areas of any plant.

Turbulating Combustion Chamber

Working with our Process Gas Burner design, one of unique features found in any Thermal Combustor Systems is the Turbulating Combustion Chamber. Utilization of these features has paved the way for Thermal Combustor Systems to operate at the lowest temperatures possible while still providing the highest VOC destruction. Faced with today's compliance requirements the old design strategies of time and temperature are not enough. Thermal Combustor Systems meet the world's most stringent emission limits by maximizing turbulent mixing, flame impingement and temperature uniformity we can assure users of low cost and ultra high destruction.

Process Gas Burner System

The combustion system in all the Thermal Combustor Systems is designed to process your waste stream safely directly as a fuel. This saves in overall size of the system, minimizes supplemental fuel consumption, and makes for a very economical pollution control system. The Process Gas Burner System will safely distribute and inject the gasses into the Turbulating Combustion Chamber. All gas handling equipment, valving, and flame arrestors are designed and supplied to meet the highest safety levels. Unlike enclosed ground level flare systems, the TCS process burner is designed to accept ranges BTU concentrations without risk to flame-outs or lower combustion temperatures.

Insulating Systems

All Thermal Combustor Systems utilize a specialized internal insulation system that will retain heat for low cost and cool shell temperatures, while allowing fast startups and extended equipment life. The insulation system works in conjunction with the round design to eliminate fatigue for industry leading uptime reliability and the lowest maintenance costs.

Temperature Safety System

Every Thermal Combustor Systems is integrated with our customized PLC-control panel called TSS. TSS communicates with the TCS and your process for optimal performance, safety, and reliability. TSS optimizes the systems efficiency by managing temperatures, controlling the frequency drive, and positioning valves. This user-friendly system provides automated operations, one button start - stops, self-diagnostics, and data monitoring options for simplified maintenance and compliance verification.

Each Thermal Combustor System is shop assembled and in some cases, we can provide factory acceptance testing to speed field installation and commissioning.

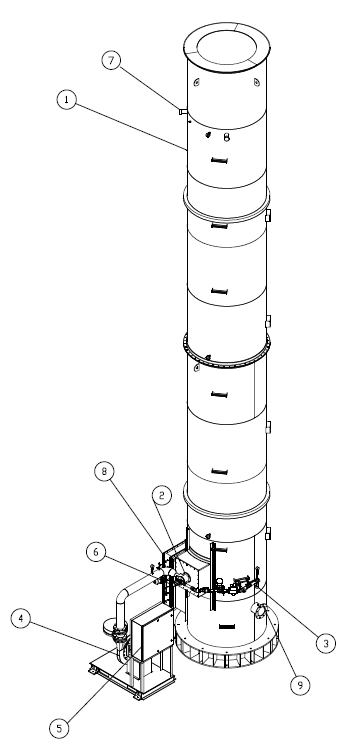

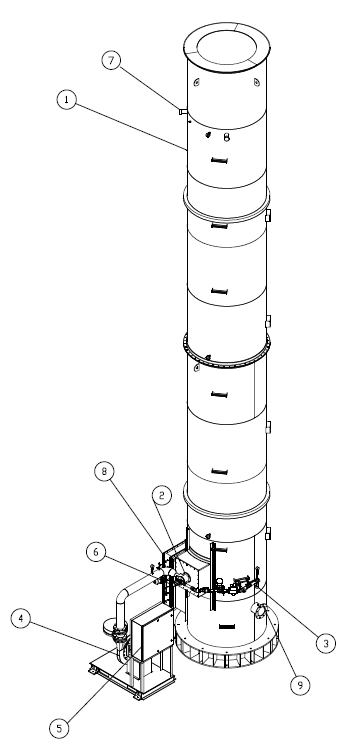

Item Description

- Combustor Stack

- Process Gas Burner

- Support Fuel Train

- Combustion Blower

- Control Panel

- UV Scanner

- Test Ports

- Fresh Air Damper

- Process Inleta

Thermal Combustor SystemS offer these standard features:

- Process gas capacities up to 100 MMBTUH

- VOC destruction up to 99.9%

- High volumetric turndowns

- Normally aspirated and Forced Draft System

- Automated operation via TSS control systems

- Pre-piped and wired components

- Compact design with installation flexibility

- Enclosed Flare structure and simplicity

%203,600%20SCFM%20Adhesive%20Manufacturing%20Emissions-1.jpg?width=250&name=CPI%20Thermal%20Combustor%20System%20(TCS)%203,600%20SCFM%20Adhesive%20Manufacturing%20Emissions-1.jpg)