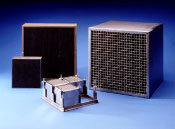

CPI has been manufacturing precious metal catalyst since 1969 and holds 14 patents for formulations or manufacturing techniques. The basis of the manufacturing process includes techniques to disperse the active precious metals over a large surface area. The METAC family of catalyst are precious metal based and include such Nobel metals as; platinum, palladium, and others electroplated onto a proprietary carrier metal. Depending on the desired results, CPI can offer a variety of noble metals and carrier metals for a long active life, with high performance characteristics.

The METAC Product Group is staffed by a number of experienced professionals with a proven background in application chemistry and analytical experience. CPI began nearly 48 years ago as a supplier of custom catalyst formulations. Today we continue our long history of catalyst application sales and service along side our Systems Group. This unique collaboration of catalyst experience with systems expertise is unmatched in our industry.

Two forms of METAC Catalyst are available: