Thermal Oxidizer

What is a Thermal Oxidizer?

A Thermal Oxidizer (also referred to as a thermal oxidizer or incinerator) is a combustion device that controls volatile organic compounds (VOCs), hazardous air pollutants ( HAPs), and odors by converting (destroying) the emissions into CO2 and H2O through the use of heat before exhausting them to the atmosphere.

Thermal Oxidizers play a crucial role in promoting sustainable industrial practices by reducing emissions, conserving resources, and minimizing environmental impact.

Thermal Oxidizers significantly reduce harmful emissions from industrial processes resulting in cleaner air and mitigating the impact on public health and the environment.

Thermal Oxidizers can achieve thermal efficiencies up to 95% and destruction efficiencies that can exceed 99%.

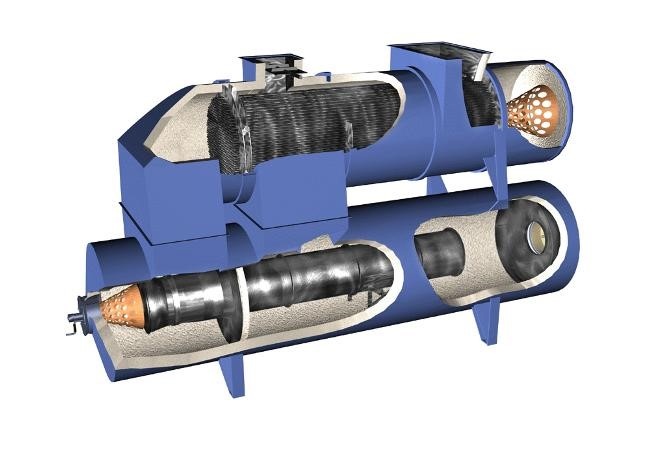

How does a Thermal Oxidizer work?

Using extreme high temperatures (1500°F) to trigger a combustion reaction, the VOCs & air pollutants are fully oxidized, transforming the organic solvents into CO2 (carbon dioxide) and H2O (water).

Oxidizer performance depends on a combination of the three T’s of combustion: Time, Temperature, and Turbulence.

- Time : Retention time, or residence time, is the length of time that a VOC/organic is at the appropriate oxidation temperature. Both retention time and residence time refer to time inside the thermal oxidizer's combustion chamber.

- Temperature: Typical temperatures in the combustion chamber range between 1400°F and 1600°F and higher. For each organic compound, a specific temperature and a specific retention time is required to achieve the desired level of destruction.

- Turbulence: Sufficient air mixing, also known as turbulence, must also be achieved.in the combustion chamber.

More About Thermal Oxidizers

Who uses Thermal Oxidizers:

Air pollution control equipment is used in nearly all industrial processing and manufacturing industries to reduce emissions of volatile organic compounds (VOCs), hazardous air pollutants (HAPs), and other greenhouse gases (GHG). CPI provides innovative and cost-conscious solutions to the most complex VOC, NOx, and Odor pollution challenges for a wide range of applications and industrial processes.

Find thermal oxidizers for your industry.

Back to the table of contents

How to decide which thermal oxidizer is right for your process:

- Initial capital cost: Each type of thermal oxidizer has a typical cost that varies based on the size of the equipment. Capital costs include equipment, shipping, installation, commissioning and startup.

- Operating cost: Annual operating costs include electricity, natural gas, compressed air (if needed), maintenance costs, and personnel.

- Break-even point: Capital and operating costs can vary widely between different thermal oxidizers. It is necessary to evaluate and understand the total cost of ownership and break-even timing when deciding which type of thermal oxidizer is the best long-term solution for your application.

- Energy usage: Energy usage increases with the required airflow and size of equipment, but varies inversely with the upfront investment cost & thermal efficiency of the system.

- Destruction efficiency: Regenerative Thermal Oxidizers (RTO) provide +98% destruction rate efficiency (DRE) while recuperative thermal oxidizers and direct-fired thermal oxidizers (DFTO) provide 99%+ DRE.

- Footprint, Weight, Size: Some types of thermal oxidizers aren't feasible at certain sizes. The size, weight, and footprint of the equipment varies inversely with energy cost.

Back to the table of contents

A

A