Electric Catalytic Oxidizer Features

VECTOR Catalytic Oxidizers meet today's environmental challenges by using the most cost effective manufacturing techniques to bring to industry reliable pollution control systems that offer lower capital costs, simplified installations, and minimal maintenance. Building the experience gained since its formation in 1969, CPI can replace the gas burner in a traditional Catalytic Oxidizer with an electric heating element.

VECTOR System's Features

VECTOR CATALYTIC OXIDIZER INTEGRATED DESIGN

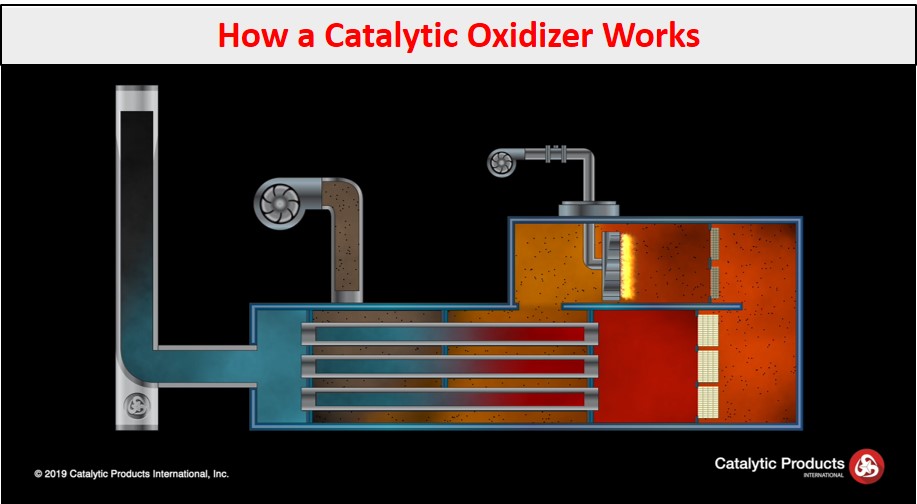

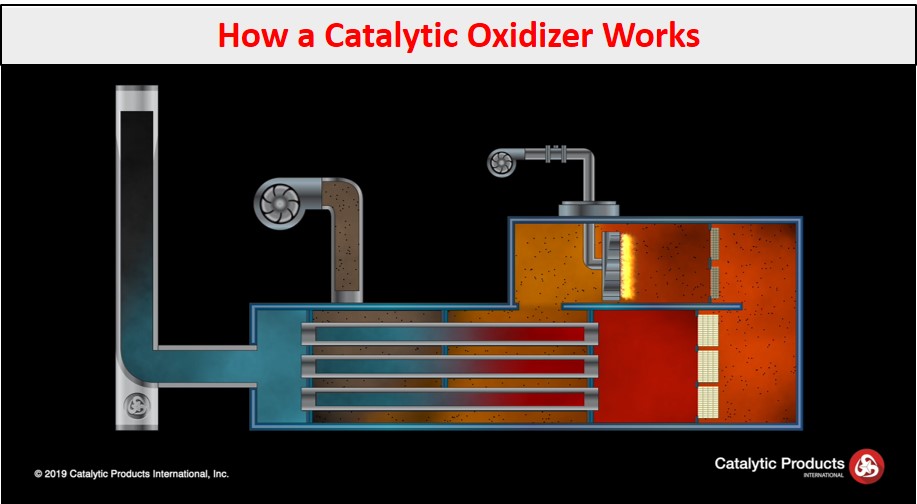

Integrating all the major components into one unitized system saves on field installations, improves reliability, and lowers the overall costs for air compliance. The VECTOR System utilizes only the highest quality components. From the all stainless steel mixing and combustion chamber, the heavy-duty, all stainless steel heat exchanger, the specialized electric heating system, to the catalyst system, each component is contained within a well insulated, maintenance-free exterior designed for long life and low costs.

Integrating all the major components into one unitized system saves on field installations, improves reliability, and lowers the overall costs for air compliance. The VECTOR System utilizes only the highest quality components. From the all stainless steel mixing and combustion chamber, the heavy-duty, all stainless steel heat exchanger, the specialized electric heating system, to the catalyst system, each component is contained within a well insulated, maintenance-free exterior designed for long life and low costs.

BEST CATALYST FOR HIGH PERFORMANCE AND LONG LIFE

Catalyst is selected based on the ability to provide the highest performance and longest life. The catalyst choices can include precious metal group metals on a monolith support, or a pourable bead. Each group offers individual benefits for each application. Monolith catalyst groups are used for general industrial applications or for specialized . emissions.

For beaded catalyst products, poison-resistant catalyst provides resistance to many common contaminates, while low temperature formulations allow minimal fuel input.

ELECTRICALLY HEATED OXIDIZER SYSTEMS

An integrated electrical heating element replaces the gas or oil combustion system. This flameless design is especially useful for smaller sized oxidizers and applications that require hazardous ratings or are not supported by gas fuel products. Electrically heated oxidizer systems are also available for retrofit applications to replace burners.

An integrated electrical heating element replaces the gas or oil combustion system. This flameless design is especially useful for smaller sized oxidizers and applications that require hazardous ratings or are not supported by gas fuel products. Electrically heated oxidizer systems are also available for retrofit applications to replace burners.

An electric

An electric

Integrating all the major components into one unitized system saves on field installations, improves reliability, and lowers the overall costs for air compliance. The

Integrating all the major components into one unitized system saves on field installations, improves reliability, and lowers the overall costs for air compliance. The

An integrated electrical heating element replaces the gas or oil combustion system. This flameless design is especially useful for smaller sized oxidizers and applications that require hazardous ratings or are not supported by gas fuel products.

An integrated electrical heating element replaces the gas or oil combustion system. This flameless design is especially useful for smaller sized oxidizers and applications that require hazardous ratings or are not supported by gas fuel products.