Packed Bed Scrubber

The most common type of wet scrubber is a packed bed counterflow scrubber. There are other types of scrubbers, such as cross flow, bubble plate and tray scrubbers, and more sophisticated or proprietary designs.

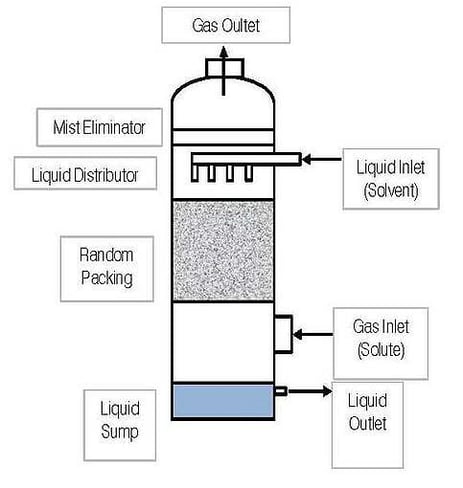

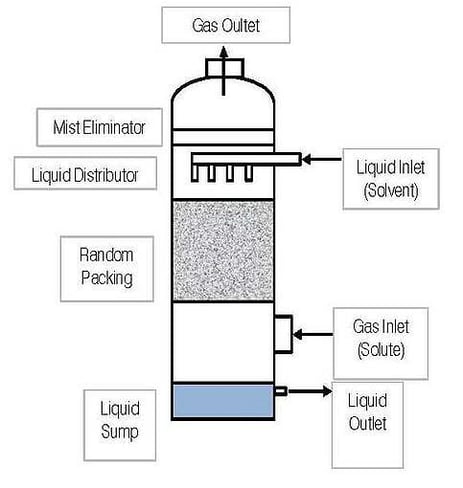

The sketch below provides a very basic flow diagram and points out the common components of a crossflow wet exhaust scrubber. The exhaust gas stream that contains the pollutants to be removed enters from the bottom of the scrubber and quickly turns upward towards the exhaust at the top of the scrubber. The random packing provides necessary surface area to distribute the liquid solvent and encourage contact between the two medias. The liquid scrubbing media (or solvent) enters near the top of the scrubber and is distributed over the random packing. The liquid adsorbs the pollutants from the gas phase and is collected in the sump of the scrubber. Prior to exiting the scrubber, the gas phase passes over a mist eliminator and exits to the atmosphere.

Water is a very common scrubbing fluid, but there are many processes or pollutants that require different fluids or solvent types. One of the determining factors in calculating the performance capability of a scrubber is understanding the pollutants’ solubility in water (the assumed scrubbing fluid in this example). Calculating the relationship of the pollutants’ solubility in a scrubbing fluid is called the absorption equilibrium.

The principle advantages of a wet scrubber for gaseous organic pollution control are low capital and installation costs and simplicity of design. However, there are a number of limitations that should be understood:

- Pollutant Removal Efficiency – Depending on the organic pollutant, the absorption equilibrium may not allow enough of the pollutant to be absorbed into the solvent, and the resultant exhaust to the atmosphere may not be adequate to meet EPA clean air act regulations. For a wide variety of VOCs, the maximum removal efficiency may only reach 90%.

- Scrubbing Liquid – Water is the most common scrubbing liquid. Water has a relatively low cost, and control loops allow for some degree of recirculation, which helps to lower the fresh water addition to the system. However, if certain pollutants require a modified solvent, additional chemical costs and control systems can quickly increase the total cost of solvent use.

- Byproducts – The principle drawback to using a wet scrubber for organic pollutant removal is the transference of an air pollution control problem to a water (liquid) pollution control problem. If the site has a water treatment plant, a study must be conducted to determine if any impact to the plant’s operation will be affected by adding the new waste stream. If the liquid waste is discharged directly to the sewer, careful examination must be conducted to insure the downstream municipality is not negatively affected, or additional fees will be incurred.

- Maintenance – For most organic pollutants, maintenance impacts will be low. However, if the target gas stream has particulates or biological impurities, these can increase the potential for plugging media, biologic growth, and pump and piping degradation.

Source: https://www.cpilink.com/blog/air-pollution-control-technology-review-absorption