How Does a Catalytic Oxidizer Work?

Catalytic destruction of VOCs and other air pollutants works by reacting the harmful air pollutants over a specially designed catalyst where VOCs are converted to CO2, water vapor (H2O), and usable heat. These harmless byproducts are passed through a heat exchanger where the gas streams energy is transferred to the incoming exhaust.

Catalytic destruction of VOCs and other air pollutants works by reacting the harmful air pollutants over a specially designed catalyst where VOCs are converted to CO2, water vapor (H2O), and usable heat. These harmless byproducts are passed through a heat exchanger where the gas streams energy is transferred to the incoming exhaust.

-

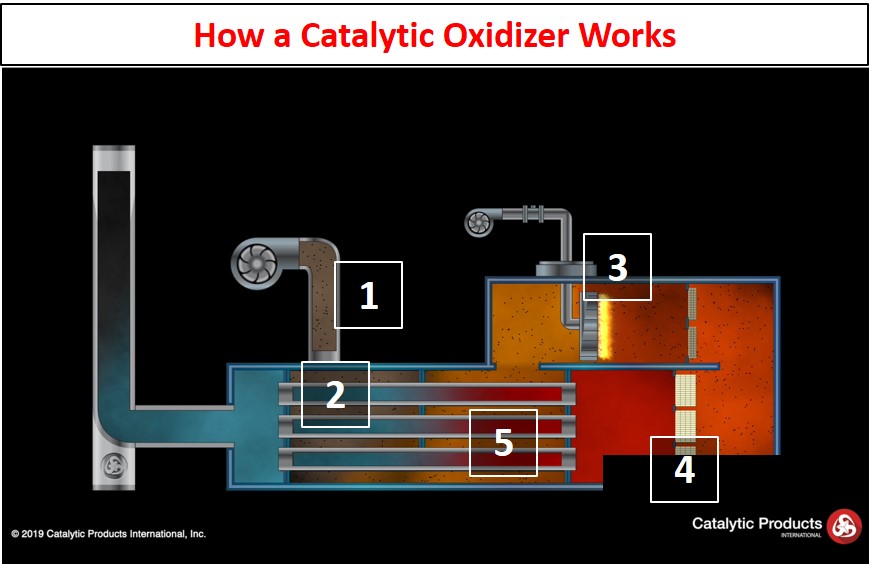

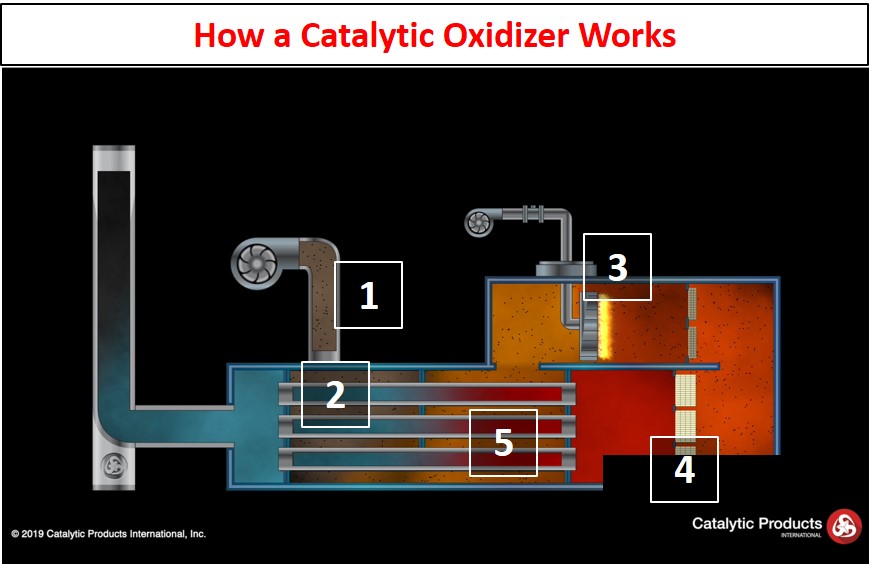

A booster fan draws VOC-laden exhaust from the process lines into the CatOx system.

-

The VOC laden exhaust is directed to our unique stainless steel primary air-to-air heat exchanger where energy is transferred to the process exhaust before passing through to the preheat burner. The main heat exchanger can eliminate the auxiliary fuel required for operation.

-

A pre-heat burner is used to maintain the desired catalyst inlet temperature precisely. The burner is designed to promote mixing of the exhaust gasses with oxygen when fired through our specialized burner plenum. This innovative design provides the highest degree of flame impingement and high-velocity mixing, leading to airflow and temperature uniformity for which CPI Catalytic Oxidizers are known.

-

The pre-heated exhaust stream then enters the catalyst bed and reacts with the specially selected catalysts where an exothermic reaction occurs, leading to complete combustion of the VOCs. The oxidation of hydrocarbons (VOCs) typically results in carbon dioxide, water vapor (H2O), and useable heat. The catalyst-induced oxidation level for most VOCs occurs at temperatures between 400 F and 750 F. This is sufficient to achieve a VOC destruction efficiency of 99%.

-

The cleaned exhaust is sent to the primary heat exchanger to give its heat up to the incoming exhaust gas for pre-heating purposes. After the primary heat exchanger, the cleaned exhaust is sent to the atmosphere or to auxiliary heating systems such as; secondary air to air recovery, air to water recovery, or directly back to the process in a closed-loop direct recirculation process.

Back to Catalytic Oxidizer Topics

Why choose a Catalytic Oxidizer?

Catalytic oxidizers are recommended for processes with low concentrations of VOCs where a TO would be impractical and an RTO would be oversized.

Catalytic Oxidizer Advantages:

- Low operating cost, low energy usage

- Ease of Operation

- Smaller footprint, easy installation

- Low maintenance (aside from catalyst poisoning and replacement)

- Higher upfront capital cost

- Prone to contamination/poisoning of catalyst

- Limited to low or moderate VOC concentrations: <25% LEL

- Cannot accommodate processes that may change their formula of VOCs (paint, coatings, etc)

Back to Catalytic Oxidizer Topics

Who uses a catalytic oxidizer?

A Catalytic Oxidizer is applied to a broad range of industrial processes especially applications with no halogenated compounds, sulfurs, silicone, or particulates. Common processes and applications using Catalytic Oxidizers include:

CPI Catalytic Oxidizers meet today's environmental challenges by using the most cost-effective manufacturing techniques to bring to industry reliable pollution control systems that offer lower capital costs, simplified installations, and minimal maintenance.

Back to Catalytic Oxidizer Topics

Features of CPI Catalytic Oxidizers

Integrated Design

Integrating all the major components into one unitized system saves on field installations, improves reliability, and lowers the overall costs of air compliance. The CPI Catalytic Oxidizer System utilizes only the highest quality components. From the all stainless steel mixing and combustion chamber, the heavy-duty, heat exchanger, the specialized burner system, to the catalyst system, each component is contained within a well insulated, maintenance-free exterior designed for long life and low costs.

Integrating all the major components into one unitized system saves on field installations, improves reliability, and lowers the overall costs of air compliance. The CPI Catalytic Oxidizer System utilizes only the highest quality components. From the all stainless steel mixing and combustion chamber, the heavy-duty, heat exchanger, the specialized burner system, to the catalyst system, each component is contained within a well insulated, maintenance-free exterior designed for long life and low costs.

Catalyst

Each CPI Catalytic Oxidizer System is custom engineered and built for maximum performance and flexibility. Therefore, the catalyst is selected based on the ability to provide the highest performance and longest life. Pressure requirements, particulate size, solvent types, concentrations, performance requirements, installation requirements all come into catalyst design consideration. The catalyst choices can include precious metal group metals on a pourable bead or a monolith support. Each group offers individual benefits for each application. For beaded catalyst products, poison-resistant catalyst provides resistance to many common contaminates while low-temperature formulations allow minimal fuel input. The most noticeable advantage about CPI Systems is found in the innovative, split-bed containment system. The catalyst is contained in a specially developed catalyst tray that offers partial catalyst replacement, faster inspections, cross-sectional analysis, and longer life. Monolith Catalyst groups are used for general industrial applications or for specialized emissions.

Each CPI Catalytic Oxidizer System is custom engineered and built for maximum performance and flexibility. Therefore, the catalyst is selected based on the ability to provide the highest performance and longest life. Pressure requirements, particulate size, solvent types, concentrations, performance requirements, installation requirements all come into catalyst design consideration. The catalyst choices can include precious metal group metals on a pourable bead or a monolith support. Each group offers individual benefits for each application. For beaded catalyst products, poison-resistant catalyst provides resistance to many common contaminates while low-temperature formulations allow minimal fuel input. The most noticeable advantage about CPI Systems is found in the innovative, split-bed containment system. The catalyst is contained in a specially developed catalyst tray that offers partial catalyst replacement, faster inspections, cross-sectional analysis, and longer life. Monolith Catalyst groups are used for general industrial applications or for specialized emissions.

Learn more about how catalyst works in a Catalytic Oxidizer: Catalytic Oxidizer General Operating Conditions

Thermal Efficiency

CPI Catalytic Oxidizer Systems lead the industry with the lowest operating costs. The primary heat exchangers are made of all high-grade stainless steels and incorporate our unique floating plate expansion system. This unique design provides for long life, high efficiency, and the ability to accommodate the highest solvent loads. Catalytic Oxidizer heat exchangers can be designed with thermal efficiencies in excess of 80% and can be equipped with fully automatic hot gas or cold gas bypass dampers for self-sustaining operations.

CPI Catalytic Oxidizer Systems lead the industry with the lowest operating costs. The primary heat exchangers are made of all high-grade stainless steels and incorporate our unique floating plate expansion system. This unique design provides for long life, high efficiency, and the ability to accommodate the highest solvent loads. Catalytic Oxidizer heat exchangers can be designed with thermal efficiencies in excess of 80% and can be equipped with fully automatic hot gas or cold gas bypass dampers for self-sustaining operations.

Interior And Exterior Construction

The CPI Catalytic Oxidizer System is fabricated entirely of stainless steel alloys designed to prevent embrittlement and fatigue. The entire unit is continuously welded to eliminate hydrocarbon leakage and provide the highest uptime reliability. All the interior components are fully insulated with a high quality lining system designed to reduce heat losses for continued energy savings.

The CPI Catalytic Oxidizer System is fabricated entirely of stainless steel alloys designed to prevent embrittlement and fatigue. The entire unit is continuously welded to eliminate hydrocarbon leakage and provide the highest uptime reliability. All the interior components are fully insulated with a high quality lining system designed to reduce heat losses for continued energy savings.

Temperature Safety System

Every CPI Catalytic Oxidizer system is integrated to our customized PLC-control panel called TSS. TSS communicates with the CPI system and your process for optimal performance, safety, and reliability. TSS optimizes fuel efficiency by managing temperatures, controlling drives, and positioning valves. This user friendly system provides automated operations, one button start-stops, self diagnostics, and data monitoring options for simplified maintenance and compliance verification. Catalytic Products International, Inc. has vast processor experience and can integrate any industrial processor into your operations.

Every CPI Catalytic Oxidizer system is integrated to our customized PLC-control panel called TSS. TSS communicates with the CPI system and your process for optimal performance, safety, and reliability. TSS optimizes fuel efficiency by managing temperatures, controlling drives, and positioning valves. This user friendly system provides automated operations, one button start-stops, self diagnostics, and data monitoring options for simplified maintenance and compliance verification. Catalytic Products International, Inc. has vast processor experience and can integrate any industrial processor into your operations.

Back to Catalytic Oxidizer Topics

Integrating all the major components into one unitized system saves on field installations, improves reliability, and lowers the overall costs of air compliance. The CPI Catalytic Oxidizer System utilizes only the highest quality components. From the all stainless steel mixing and combustion chamber, the heavy-duty, heat exchanger, the specialized burner system, to the catalyst system, each component is contained within a well insulated, maintenance-free exterior designed for long life and low costs.

Integrating all the major components into one unitized system saves on field installations, improves reliability, and lowers the overall costs of air compliance. The CPI Catalytic Oxidizer System utilizes only the highest quality components. From the all stainless steel mixing and combustion chamber, the heavy-duty, heat exchanger, the specialized burner system, to the catalyst system, each component is contained within a well insulated, maintenance-free exterior designed for long life and low costs. Each CPI

Each CPI

The CPI Catalytic Oxidizer System is fabricated entirely of stainless steel alloys designed to prevent embrittlement and fatigue. The entire unit is cont

The CPI Catalytic Oxidizer System is fabricated entirely of stainless steel alloys designed to prevent embrittlement and fatigue. The entire unit is cont Every CPI Catalytic Oxidizer system is integrated to our customized PLC-control panel called TSS. TSS communicates with the CPI system and your process for optimal performance, safety, and reliability. TSS optimizes fuel efficiency by managing temperatures, controlling drives, and positioning valves. This user friendly system provides automated operations, one button start-stops, self diagnostics, and data monitoring options for simplified maintenance and compliance verification. Catalytic Products International, Inc. has vast processor experience and can integrate any industrial processor into your operations.

Every CPI Catalytic Oxidizer system is integrated to our customized PLC-control panel called TSS. TSS communicates with the CPI system and your process for optimal performance, safety, and reliability. TSS optimizes fuel efficiency by managing temperatures, controlling drives, and positioning valves. This user friendly system provides automated operations, one button start-stops, self diagnostics, and data monitoring options for simplified maintenance and compliance verification. Catalytic Products International, Inc. has vast processor experience and can integrate any industrial processor into your operations.