- Our Company

- Products

- Catalytic Oxidizers

- Regenerative Thermal Oxidizer (RTO)

- Thermal Oxidizers

- Electric Catalytic Oxidizer

- Ductwork

- Filtration Systems

- Heat Exchangers

- Heat Recovery Systems

- Incinerators

- Installation Services

- Pre-Owned Equipment

- Rotary Concentrator

- Selective Catalytic Reduction

- Thermal Combustor System

- Wet Scrubber

- Aftermarket Services

- Industries

- Automotive

- Bakery Oven VOC Control

- Ceramic Manufacturing

- Chemical Processing & VOC Control

- Coffee Roasting

- Coil Coating

- Drum & Container Painting

- Flavoring & Fragrance

- Flexographic Printing & VOC Control

- Food Processing VOC Control

- Metal Decorating

- Metal Recycling & Shredding VOC Control

- Oil & Gas Processing

- Paint & Surface Coating

- PFAS Air Emissions Control

- Pharmaceutical & Medical

- Renewable Fuels

- Renewable Natural Gas (RNG)

- Rubber Products

- Semiconductor & Electronic

- Web Coating & Converting

- Case Studies

- Resource Center

- Request a Quote

- Our Company

- Products

- Catalytic Oxidizers

- Regenerative Thermal Oxidizer (RTO)

- Thermal Oxidizers

- Electric Catalytic Oxidizer

- Ductwork

- Filtration Systems

- Heat Exchangers

- Heat Recovery Systems

- Incinerators

- Installation Services

- Pre-Owned Equipment

- Rotary Concentrator

- Selective Catalytic Reduction

- Thermal Combustor System

- Wet Scrubber

- Aftermarket Services

- Industries

- Automotive

- Bakery Oven VOC Control

- Ceramic Manufacturing

- Chemical Processing & VOC Control

- Coffee Roasting

- Coil Coating

- Drum & Container Painting

- Flavoring & Fragrance

- Flexographic Printing & VOC Control

- Food Processing VOC Control

- Metal Decorating

- Metal Recycling & Shredding VOC Control

- Oil & Gas Processing

- Paint & Surface Coating

- PFAS Air Emissions Control

- Pharmaceutical & Medical

- Renewable Fuels

- Renewable Natural Gas (RNG)

- Rubber Products

- Semiconductor & Electronic

- Web Coating & Converting

- Case Studies

- Resource Center

- Request a Quote

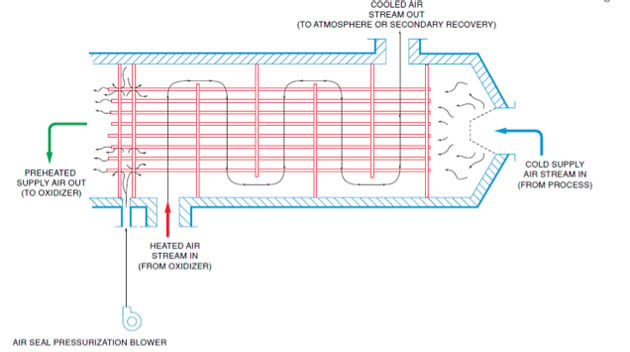

CPI has been a leader in the design and manufacture of catalytic and thermal oxidizers since 1969. Our custom engineered products have paved the way for continuous improvements in the traditional methods of design and manufacture. Throughout our years of experience, we have noticed an increasing market demand for improved heat exchanger designs. Our specialized design/applications team has approached this problem head-on with outstanding results. The FLOATING TUBE air-to-air heat exchanger by CPI has proven to be an innovative solution to an industry wide problem. As a designer and manufacturer of catalytic and thermal oxidizers since 1969, our focus has always been towards the continuing development of high quality, long-lasting pollution control equipment. Throughout our long history and experience, we recognized a common problem with many of the industry’s oxidation equipment - short equipment life, unreliable systems, and heavy maintenance costs have burdened users for too long. Keeping pace with the needs of an industry is not always an easy task. Specifically by revolutionizing air-to-air primary heat exchangers. Traditional shell and tube heat exchangers are very simple devices that transfer heat energy from one air stream to another. Heat exchangers are used for energy conservation in a multitude of applications, the most common being in thermal oxidation systems. Shell and tube primary heat exchanger are commonly made of stainless steel tubes welded to tube sheets and use a series of baffles to direct air over the tubes. The concept is simple, but the physics and engineering for success are complicated. As many suppliers and users have come to realize, controlling the thermal-mechanical stresses in high-temperature shell and tube heat exchangers is a difficult task. The traditional heat exchanger typically incorporates an expansion joint to absorb the tremendous thermal growth encountered inside of these systems. Throughout the operation of a heat exchanger, varying temperatures, differential expansion, and thermal cycling will put an incredible amount of stress on these metallic components. This uncontrollable stress is the cause for premature and structural failure and unacceptable performance. Heat exchangers using old expansion joint designs will present users with cracked welds, internal leakage, bent baffles and tube sheets, or melted and exploded tubes. These very common problems are the reason that we developed, designed, and have refined our FLOATING TUBE shell and tube heat exchanger.

CPI has been a leader in the design and manufacture of catalytic and thermal oxidizers since 1969. Our custom engineered products have paved the way for continuous improvements in the traditional methods of design and manufacture. Throughout our years of experience, we have noticed an increasing market demand for improved heat exchanger designs. Our specialized design/applications team has approached this problem head-on with outstanding results. The FLOATING TUBE air-to-air heat exchanger by CPI has proven to be an innovative solution to an industry wide problem. As a designer and manufacturer of catalytic and thermal oxidizers since 1969, our focus has always been towards the continuing development of high quality, long-lasting pollution control equipment. Throughout our long history and experience, we recognized a common problem with many of the industry’s oxidation equipment - short equipment life, unreliable systems, and heavy maintenance costs have burdened users for too long. Keeping pace with the needs of an industry is not always an easy task. Specifically by revolutionizing air-to-air primary heat exchangers. Traditional shell and tube heat exchangers are very simple devices that transfer heat energy from one air stream to another. Heat exchangers are used for energy conservation in a multitude of applications, the most common being in thermal oxidation systems. Shell and tube primary heat exchanger are commonly made of stainless steel tubes welded to tube sheets and use a series of baffles to direct air over the tubes. The concept is simple, but the physics and engineering for success are complicated. As many suppliers and users have come to realize, controlling the thermal-mechanical stresses in high-temperature shell and tube heat exchangers is a difficult task. The traditional heat exchanger typically incorporates an expansion joint to absorb the tremendous thermal growth encountered inside of these systems. Throughout the operation of a heat exchanger, varying temperatures, differential expansion, and thermal cycling will put an incredible amount of stress on these metallic components. This uncontrollable stress is the cause for premature and structural failure and unacceptable performance. Heat exchangers using old expansion joint designs will present users with cracked welds, internal leakage, bent baffles and tube sheets, or melted and exploded tubes. These very common problems are the reason that we developed, designed, and have refined our FLOATING TUBE shell and tube heat exchanger.