Process

Catalytic Products International, Inc designs each QUADRANT SRS Thermal Oxidizer based on the exact needs of your application. With 48 years of thermal oxidizer design as a basis of our expertise, you can be assured that your QUADRANT SRS Thermal Oxidizer will be designed with the most appropriate features for your needs. The QUADRANT SRS Thermal Oxidizer is an economical solution to applications in the silicone tape coating, release liner, adhesive coating, and other processes that use silicone in the manufacturing operations.

Silicon is a necessary additive for various coated products. Silicone is vaporized in the drying process that forces a large percentage into the dryer exhaust. Silicone when heated above certain temperatures will form an inorganic particulate - Silicon DiOxide (SiO2) SiO2 clings to hot metallic surfaces and forms a destructive and efficiency robbing barrier layer. SiO2 will poison catalytic oxidizers. SiO2 can effect RTO valving and clog ceramic media. SiO2 will create boundary layers in typical shell and tube heat exchangers.

Catalytic Products International developed the QUADRANT SRS Thermal Oxidizer to provide an economical answer to the disastrous effects of SiO2 This special design addresses the following:

Catalytic Products International developed the QUADRANT SRS Thermal Oxidizer to provide an economical answer to the disastrous effects of SiO2 This special design addresses the following:

Engineered cleanabiilty Easy access Fast and effective clean-out Automatic Notification Cleaning tools to speed up the cleaning operation.

Among the air pollution control choices available to consider; Catalytic Oxidation, Thermal (recuperative) Oxidation, and Regenerative Thermal Oxidation, all are susceptible to operational problems of one kind or another. The basis for these problems stems from the oxidation process itself. During operation of the production source, silicones are driven off along with the VOC's. Since the air pollution control equipment is installed to destroy the VOC's, any system has to be designed to also process the silicone vapors. During the oxidation process, silicone will convert to silicon dioxide (SiO2). This (SiO2) is the culprit for failing and/or under-preforming air pollution control equipment. The SiO2 is a talcum-powder like substance that clings to metal surfaces, robbing any system of efficiency and putting at risk the system's ability to effectively destroy VOC's.

Thermal treatment of VOC's and other air pollutants works by a simple reaction of the harmful air pollutants with oxygen and heat. In this environment the VOC's are converted to harmless inert byproducts, water vapor (H2O), and usable heat. These harmless by-products are released to atmosphere or use an energy recovery technique to further lower the operational costs.

QUADRANT SRS Series Thermal Oxidizer's are considered among the world's most advanced recuperative thermal oxidation systems. These specially designed and proven systems combine the basic principles of time, temperature, and turbulence to the fullest extent possible. The resulting effects provide you with exceptional performance, substantially reduced operating costs, and industry-leading reliability.

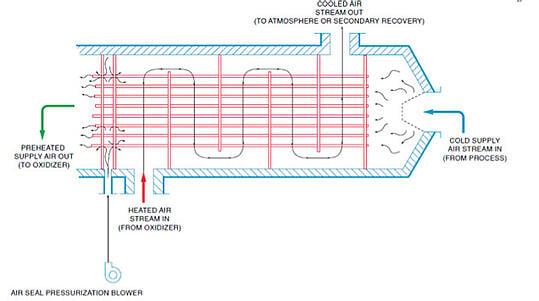

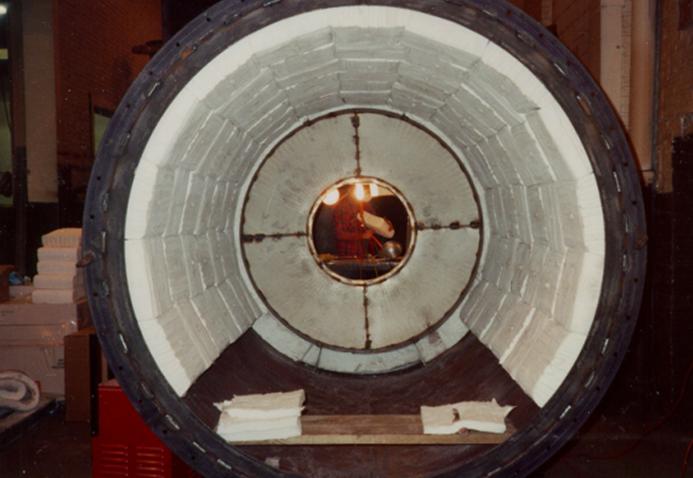

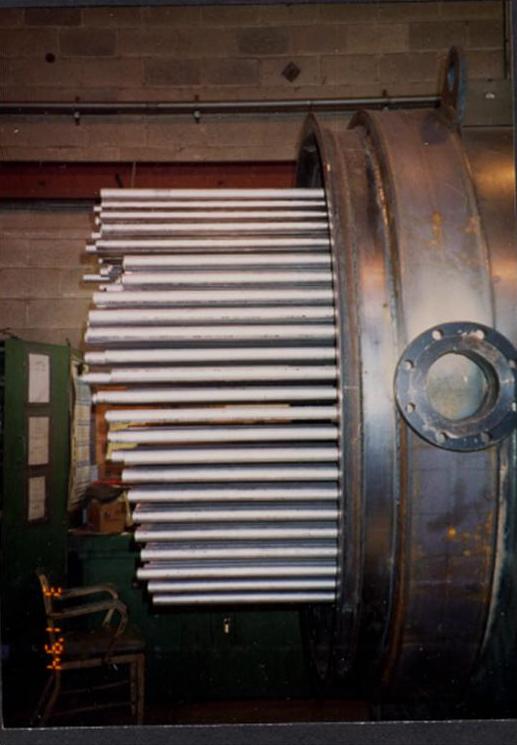

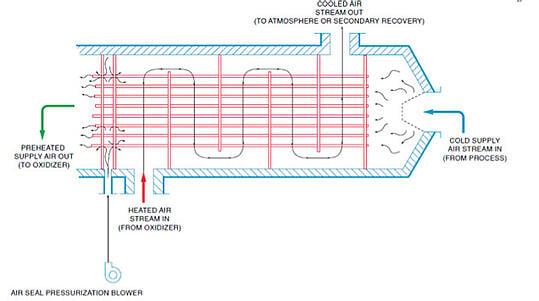

The QUADRANT Thermal Oxidation process begins with a booster fan designed to draw the volatile organic compound (VOC) laden process exhaust to the QUADRANT System. From there, the VOC and Silicone-laden process air stream is then directed to the FLOATING TUBE heat exchanger shell side, thus there is never any build up on the outside of tubes. This unique design pinpoints the tube velocities to minimize buildup and specially designed plenums force drop-out and easy access for vacuum removal. When the stream enters the FLOATING TUBE heat exchanger, it is continuously preheated at close to the ignition temperature before being sent to the pre-heat burner. The exchange of energy in the primary heat exchanger makes up the basis for fuel savings and economical operation.

A pre-heat burner is used to precisely maintain the combustion chamber operating temperature. The burner is designed to promote mixing of the exhaust gases with oxygen when fired through our specialized combustion system. This innovative design provides the highest degree of flame impingement and high-velocity mixing, leading to airflow and temperature uniformity for which QUADRANT Oxidizers are known.

The contaminated air stream next passes through a specially designed combustion profile. The combustion profile works like mixing baffles to create turbulence and improves mixing, helping to prevent temperature stratification. From there the air stream enters the dual pass combustion chamber to assure proper mixing of all the effluent constituents. Even at low flow conditions, this mixing action provides the highest possible temperature uniformity for industry leading destruction ability at the lowest operational cost.

QUADRANT SRS Thermal Oxidizers guarantee success because of these innovative design characteristics: