Many pollutants, both natural and synthetic, are gaseous in nature and require specific technology to effectively remove the pollutant from an exhaust or process gas stream. Gaseous industrial pollutants can include:

- Acid Gases (hydrochloric acid, sulfuric acid, hydrogen sulfide, and many others)

- Inorganic Gases (Sulfur Oxides, Nitrogen Oxides, Ammonia, etc.)

- Organic Gases (Ethylene, Benzene, Ethanol, and many other volatile organic compounds [VOCs] or hazardous air pollutants [HAPs])

There are several technologies available that can provide control (removal) of gaseous pollutants. This blog will provide a review of absorption as an air pollution control technology for organic pollutants. Future blogs will examine other technologies that may provide an alternative to oxidation/incineration.

While CPI does not provide all of the available technologies, we do take our consultative application analysis seriously, and when a more appropriate technology may offer some advantage, we will present other treatment options to our clients.

ABSORPTION

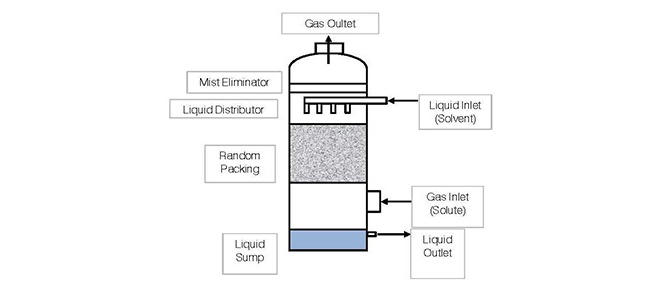

Absorption is a physical or chemical process of removing a pollutant from a gas phase media by dissolving the pollutant into a solvent media. Solvent media is most commonly a liquid phase, but can be a dry bulk solid in certain systems. The material that absorbs is called the solvent, and the gas that is to be absorbed is called the solute.

Absorption is a physical or chemical process of removing a pollutant from a gas phase media by dissolving the pollutant into a solvent media. Solvent media is most commonly a liquid phase, but can be a dry bulk solid in certain systems. The material that absorbs is called the solvent, and the gas that is to be absorbed is called the solute.

The most common form of absorption is wet scrubbing. A wet scrubber is the generic name of a control device that uses the process of absorption to separate the pollutant from a gas stream.

The most common type of wet scrubber is a packed-bed counterflow scrubber. Other types of scrubbers include cross flow, bubble plate and tray scrubbers, and more sophisticated or proprietary designs.

Acid gas scrubbing is one of the most common applications for a wet, packed tower scrubber. An Acid Gas Scrubber controls emissions which are the result of oxidizing halogenated compounds such as HCl, H2S, and SO2, which may may form acid gases during the oxidization process in a thermal oxidizer.

The principle advantages of a wet scrubber for gaseous organic pollution control are low capital and installation costs and simplicity of design. However, there are a number of limitations that should be understood:

- Pollutant Removal Efficiency – Depending on the organic pollutant, the absorption equilibrium may not allow enough of the pollutant to be absorbed into the solvent, and the resultant exhaust to the atmosphere may not be adequate to meet EPA clean air act regulations. For a wide variety of VOCs, the maximum removal efficiency may only reach 90%.

- Scrubbing Liquid – Water is the most common scrubbing liquid. Water has a relatively low cost, and control loops allow for some degree of recirculation, which helps to lower the fresh water addition to the system. However, if certain pollutants require a modified solvent, additional chemical costs and control systems can quickly increase the total cost of solvent use.

- Byproducts – The principle drawback to using a wet scrubber for organic pollutant removal is the transference of an air pollution control problem to a water (liquid) pollution control problem. If the site has a water treatment plant, a study must be conducted to determine if any impact to the plant’s operation will be affected by adding the new waste stream. If the liquid waste is discharged directly to the sewer, careful examination must be conducted to insure the downstream municipality is not negatively affected, or additional fees will be incurred.

- Maintenance – For most organic pollutants, maintenance impacts will be low. However, if the target gas stream has particulates or biological impurities, these can increase the potential for plugging media, biologic growth, and pump and piping degradation.

Absorption is just one of the technologies used to remove gaseous pollutants. As mentioned, there are several other technologies that provide air pollution control, as well. Stay tuned as we will be covering the following in upcoming blogs:

In the meantime, If you have any questions, please feel free to contact us.