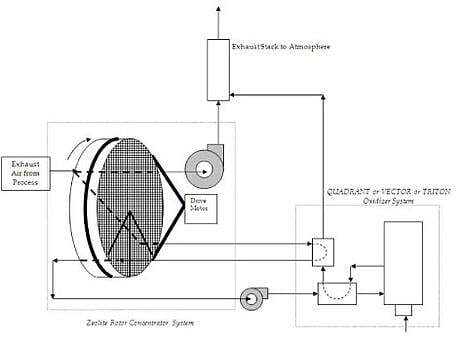

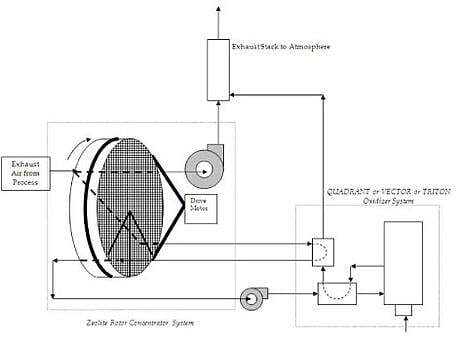

How a VOC Concentrator Works

The VOC Concentrator rotor is divided into three (3) sectors, adsorption, desorption and cooling.

Adsorption Sector

The VOC laden air passes through the adsorption sector of the rotor where the VOC's are removed from the process stream and adsorbed onto the Zeolite honeycomb media.

The process exhaust exits the adsorbent section without most of the VOC and is exhausted to the atmosphere. The adsorption section is about 84% of the rotor’s media.

Desorption Sector

As the rotor rotates the next sector is the desorption section. The Zeolite honeycomb adsorbent contains most the VOC from the process exhaust. When a smaller and warmer gas stream is passed through the Zeolite media the VOC are released into the desorption gas flow. The desorption gas flow is generally between 5% and 20% of the process exhaust with 10% for most of the VOC present in industrial operations. The desorption flow is then directed to a thermal oxidizer for destruction of the VOC. The oxidizer can be a recuperative thermal oxidizer or regenerative thermal oxidizer. Desorption temperatures range in most cases from 350 °F to 400 °F, higher temperatures can be used with equipment modifications to desorb VOC with higher boiling points. The desorption sector of the rotor is approximately 8% of the Zeolite media.

Cooling Sector

To improve the overall performance of the rotary concentrator, a portion of the process exhaust, 5% to 20% is used to cool the Zeolite media in the cooling sector following the desorption sector. This allows for better adsorption when the rotor enters the adsorption sector since the Zeolite adsorbent has been cooled in the cooling sector. The process air that is used for cooling is then heated to the desorption temperature using either a heat for the oxidizer, often using a heat exchanger or with a separate desorption heater which is then used in the desorption sector. Like the desorption sector the cooling sector comprises approximately 8% of the Zeolite media.

Air Volume Capacity

Each rotary concentrator module is capable of processing gas flow rates from approximately 7,000 SCFM to over 90,000 SCFM depending on the process and other conditions. If greater process flows exist multiple modules are combined to provide an overall abatement system.

Removal Efficiency (DRE)

The rotor concentrator removal efficiency is dependent on several factors, such as process exhaust temperature, humidity, breakdown of the VOC in the process exhaust and the overall performance required, with efficiencies in the 95% to 97% range and in some case as high as 99%.

The overall VOC destruction efficiency is obtained by multiplying the rotor concentrator removal efficiency with the destruction efficiency, for example, the rotor concentrator VOC removal efficiency is 95% and the RTO destruction efficiency is 98% the overall destruction removal efficiency (DRE) is 0.95 x 0.98 = 0.9310 or 93.1%.

VOC Concentrator Applications

Processes which include large air volume and low VOC loading are well suited for using a rotary concentrator system (RCS) and oxidizer for VOC control include:

There are other applications that may be suited to VOC control with a rotor concentrator and oxidizer after evaluation by Catalytic Products.

Features

VOC Concentrator Systems offer the following features:

MODULAR TECHNOLOGY

MODULAR TECHNOLOGYRotary Concentrators are modular in construction. A single module can accept exhaust rates up to 90,000 scfm. When larger air volumes are required, multiple modules would be used, or in some instances, double rotors can be used.