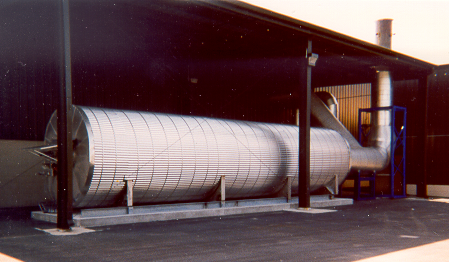

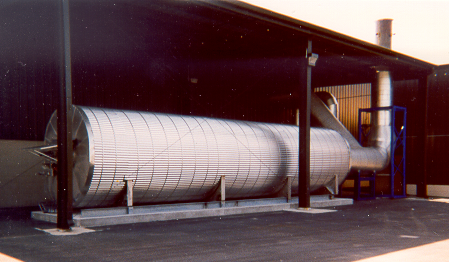

The QUADRANT IR-Series Thermal Oxidizer is unlike any traditional thermal oxidizer. The system employees numerous features that have been developed and improved upon for over three generations. The foundation of the QUADRANT IR-Series Thermal Oxidizer is our proprietary FLOATING TUBE PRIMARY HEAT EXCHANGER. This design eliminates thermal stress and fatigue by allowing each individual tube to expand and contract at its own rate. No one else has this proven technology, no one else can match the stress free durability, no one else has the application experience to meet your needs.

Thermal treatment of VOC's and other air pollutants works by a simple reaction of the harmful air pollutants with oxygen and heat. In this environment the VOC's are converted to harmless inert byproducts, water vapor (H2O), and usable heat. These harmless by-products are released to atmosphere or use an energy recovery technique to further lower the operational costs.

Thermal treatment of VOC's and other air pollutants works by a simple reaction of the harmful air pollutants with oxygen and heat. In this environment the VOC's are converted to harmless inert byproducts, water vapor (H2O), and usable heat. These harmless by-products are released to atmosphere or use an energy recovery technique to further lower the operational costs.

The QUADRANT Thermal Oxidation process begins with a booster fan designed to draw the volatile organic compound (VOC) laden process exhaust to the QUADRANT System. From there, the VOC-laden process air stream is then directed into the elongated condensate evaporate section where the exhaust gas is preheated to eliminate any vapor droplets before entering the FLOATING TUBE primary heat exchanger. This step protects the leading edge of the heat exchanger from condensate build-up and subsequent preignition. When the stream enters the FLOATING TUBE heat exchanger, it is continuously preheated at close to the ignition temperature before being sent to the pre-heat burner. The exchange of energy in the primary heat exchanger makes up the basis for fuel savings and economical operation.

A pre-heat burner is used to precisely maintain the combustion chamber operating temperature. The burner is designed to promote mixing of the exhaust gases with oxygen when fired through our specialized combustion system. This innovative design provides the highest degree of flame impingement and high-velocity mixing, leading to airflow and temperature uniformity for which QUADRANT Oxidizers are known.

The contaminated air stream next passes through an elongated high velocity combustion chamber. Here a series strategically placed mixing baffles creates turbulence and improves mixing, helping to prevent temperature stratification. This mixing action provides the highest possible temperature uniformity for industry leading destruction ability at the lowest operational cost. Once mixed the air stream is held in the dwell chamber long enough to ensure complete combustion of the VOC's. Next the oxidized gases are directed to the FLOATING TUBE primary heat exchanger where the energy is transferred from the clean-oxidized gas to the incoming dirty process exhaust.

Some applications benefit from auxiliary heating systems such as; secondary air to air recovery, air to water recovery, air to oil recovery, or directly back to the process in a closed loop direct recirculation process.

Your process is now in compliance with all clean air regulations !!