Many pollutants, both natural and synthetic, are gaseous in nature and require specific technology to effectively remove the pollutant from an exhaust or process gas stream. Gaseous industrial pollutants can include:

- Acid Gases (hydrochloric acid, sulfuric acid, hydrogen sulfide, and many others)

- Inorganic Gases (Sulfur Oxides, Nitrogen Oxides, Ammonia, etc.)

- Organic Gases (Ethylene, Benzene, Ethanol, and many other volatile organic compounds [VOCs] or hazardous air pollutants [HAPs])

There are several technologies available that can provide control (removal) of gaseous pollutants. This blog will provide you with a high level description and review of Biological Control as an air pollution control technology for organic pollutants.

While CPI does not provide all of the available technologies, we do take our consultative application analysis seriously, and when a more appropriate technology may offer some advantage, we will present other treatment options to our clients.

If you missed the previous technology review blogs about Absorption, Adsorption, or Condensation, please follow those links to read more.

Biological Control

Biological control systems can be used to remove gaseous pollutants from a process stream by aerobic digestion or consumption by microbes. Biological systems can be effective on certain VOC species and some inorganic compounds. This technology is mostly effective for treating low concentrations of pollutants contained in large gas volumes. The technology is also applied in waste water treatment schemes, but this blog will focus specifically on biological control systems for air pollution abatement.

Biological control systems can be segmented into three types of designs:

- Biofilters – the most basic system, best applied to very low concentrations

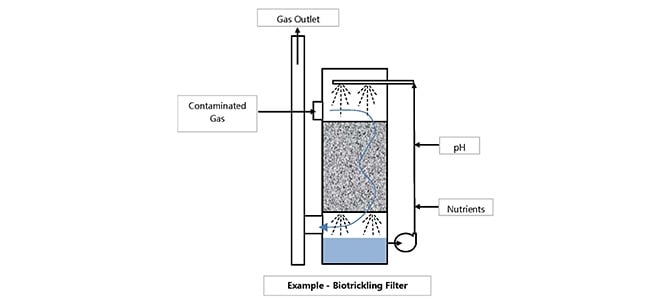

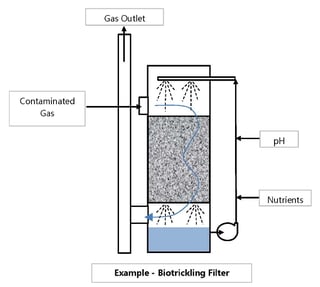

- Biotrickling filters – more complicated systems which can use nutrient and pH dosing

- Bioscrubbers – similar to the scrubbers used in the absorption process, but bioscrubbers use a microbe containing recirculation solution

Biofilters and Biotrickling filters are the most common technology in use in the United States. Bioscrubbers are more common in Europe. The biological system is typically comprised of three parts:

- A porous medium – a material such as compost, peat, soil, or ceramic or plastic packing. This is really a support structure for the micro-organism. It is sometimes referred to as the packing media.

- A bio-film – a layer attached to the packing media that provides a means for the polluted compounds to be diffused onto the micro-organism.

- A micro-organism – the active cell that utilizes the organic contaminates as food. To promote microbe growth and activity, the bed is kept moist, and the gas stream is humidified.

Biofilters have been in use for decades as odor abatement systems at wastewater treatment plants, rendering plants, and various industrial facilities. More recently, biofilters have been used for VOC abatement where concentrations of VOC are very low but are contained in large exhaust streams. Some common pollutants that work well in biofiltration systems can include: ammonia, hydrogen sulfide and other sulfur based organics, various mercaptans and aldehydes, chlorinated organic and aromatic hydrocarbons. Degradation rates of 50% to 90% can be achieved for most of the listed VOCs. However, halogens are expected to be on the lower end of this range and can cause premature aging of the microbes.

A biotrickling filter is more complicated than the simple biofilter. In this type of filter, the porous medium is contained in a vessel that is subjected to a nutrient and pH dosed solution that is “trickled down” over the medium and interacts with the polluted gas stream. The selection of the appropriate packing media for a biotrickling filter is important to the performance of the system. Random plastic media, as commonly used in gas scrubbing applications, is typically used. Nutrient selection and availability is also a key factor in a biotrickling filter's performance. Major nutrients required for microbial growth can be nitrogen, phosphorus, calcium, and magnesium. pH control is required to neutralize acidic by-products and production. pH is ideally controlled to neutral conditions.

The use of biological control systems as an air pollution control or VOC abatement device has wide acceptance. These systems are particularly popular for odorous gas streams, where the offending odor is caused by very low concentrations of organic materials. However, there are a number of limitations that should be understood:

- In general, organic concentrations of more than 100 ppm may not be capable of meeting EPA regulatory expectations. At high VOC concentrations, microbial growth can result in clogging of the media pour spaces, while in some cases, high concentrations can be toxic to the microbe and inhibit biodegradation.

- The pollutant compound must be biodegradable under aerobic conditions.

- Compound solubility can range many times between common or different VOCs. Polluted gas streams with a variety of VOCs may present performance issues for certain types of VOC.

- The polluted air stream should be relatively low in temperature. A good rule of thumb is that temperatures should be held near 75°F to 95°F for most applications. This could mean some form of gas cooling is required for hot exhaust streams.

- Acidic by-product formation may result when organic sulfides or halogens are contained in the off gas.

- A period of several days to several weeks is usually required for the microbe population to acclimate to the pollutant and for the VOC degraders to grow to a point where full performance can be achieved.

- Dust and particulates can clog the media and require frequent replacement. Certain applications are more susceptible to media plugging due to the nature of the exhaust.

Biological control systems are just one of the technologies used to remove gaseous pollutants from contaminated air streams. As previously described, there are several other technologies that provide air pollution control. Consider revisiting these blogs:

In the meantime, if you have any questions, please feel free to contact us.