Many pollutants, both natural and synthetic, are gaseous in nature and require specific technology to effectively remove the pollutant from an exhaust or process gas stream. Gaseous industrial pollutants can include:

- Acid Gases (hydrochloric acid, sulfuric acid, hydrogen sulfide, and many others)

- Inorganic Gases (Sulfur Oxides, Nitrogen Oxides, Ammonia, etc.)

- Organic Gases (Ethylene, Benzene, Ethanol, and many other volatile organic compounds [VOCs] or hazardous air pollutants [HAPs])

There are several technologies available that can provide control (removal) of gaseous pollutants. This blog will provide you with a high level description and review of Condensation as an air pollution control technology for organic pollutants. Future blogs will examine other technologies that may provide an alternative to oxidation/incineration.

While CPI does not provide all of the available technologies, we do take our consultative application analysis seriously, and when a more appropriate technology may offer some advantage, we will present other treatment options to our clients.

If you missed the previous technology review blogs about Absorption or Adsorption you can follow the links to read them here.

CONDENSATION

Condensation is a process used heavily throughout industry to convert a gas or vapor to liquid. Any gas can be reduced to a liquid by sufficiently lowering the temperature (or increasing the pressure). Common examples can include distillation of various hydrocarbons in refining operations and drying of air. Condensation can be used to remove a pollutant from a gas stream if the dew point of the pollutant is higher than the carrier gas (or non-pollutant gas). If this is true, the total gas stream can be reduced in temperature to below the pollutant’s dew point, which will then separate the pollutant from the remaining gas stream as a liquid.

The most common form of condensing is by lowering temperature. While increasing pressure can be equally effective, a pressure condensing technique is usually more expensive. Condensers are simple and relatively inexpensive devices that normally use water or air as the coolant. In other, more sophisticated condensers, a cryogenic method will reduce gas stream temperatures by several hundred degrees.

Condensers are not widely used as standalone air pollution control devices, since their limited removal efficiency may not be adequate to meet Federal or State EPA Clean Air Act requirements. The more common use for condensers is as pre-treatment devices. Condensers can be used in front of absorbers, adsorbers, and oxidizers to reduce the total gas volume treated or to selectively remove certain organic compounds from the gas stream for re-use in the process or some form of beneficial use recovery. The final selection of the condenser will be based on many factors, such as intended goals, contaminated air stream composition, available types of coolants, condensate recovery value, etc.

Condensers work when the warmer vapor stream contacts a cooling medium. The heat from the warm gases is transferred to the cooler medium. Then, as the warm gas stream begins to cool, the kinetic energy of the gas is reduced. Condensation occurs because the pollutant molecules are slowed and crowded so close together that the attractive forces between the molecules cause them to condense into a liquid. This phenomenon is known as the van der Waals forces.

Since the more common condensation device in air pollution control is based on lowering temperatures (as opposed to increasing pressure), there are two different methods of accomplishing this.

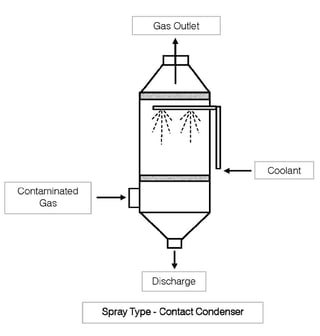

Direct contact condensers - These are usually simple, low cost devices which operate by mixing the contaminated gas stream with the cooling medium.. The condensate usually cannot be re-used because of contamination by the coolant. The bulk of contact condensers use indirect or surface designs. Below is a sketch of a simple spray condenser:

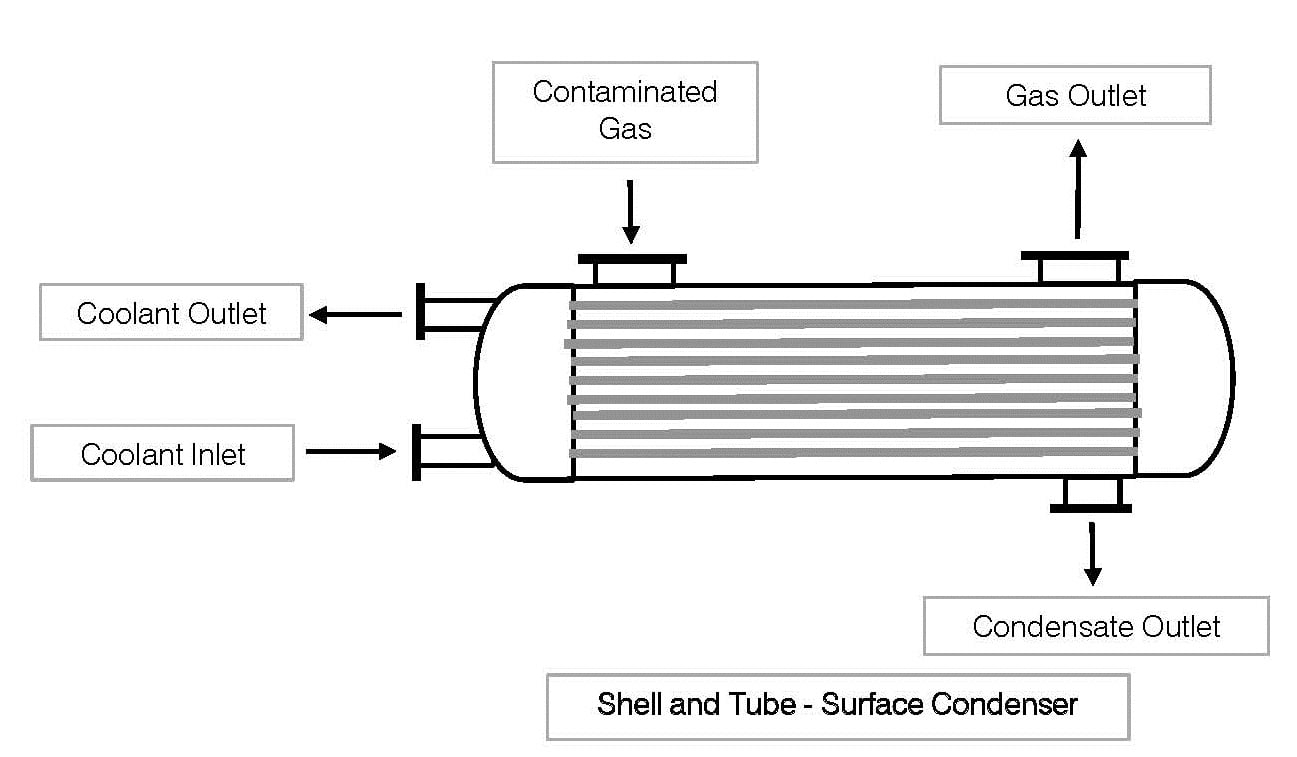

Indirect (or surface) condensers - These systems are employed extensively throughout chemical process industries. In surface condensers, the contaminated gas stream is separated by a physical barrier, with the cooling medium on the other side of the barrier, similar to a radiator or heat exchanger. Common devices types may include shell and tube, plate and frame, fin tube, and bare tube, among others. Below is a simple sketch of a shell and tube condenser:

Condensation is just one of the technologies used to remove gaseous pollutants from contaminated air streams. As mentioned, there are several other technologies that provide air pollution control, as well. Stay tuned as we will be covering the following in upcoming blogs:

- Absorption (completed, read more)

- Adsorption (completed, read more)

- Biological Filtration

- Oxidation or Incineration

In the meantime, if you have any questions, please feel free to contact us.