At CPI we have a great team of knowledgeable, dedicated professionals that bring years of experience to the work that we do in providing air pollution control solutions to our customers. As part of our ongoing look at maintaining your Catalytic Oxidizer (CatOx), today we're looking at catalyst maintenance.

Read More

Topics:

Air Pollution Control,

Maintenance and Repairs,

Catalytic Oxidizer,

Blog

Why should you be concerned about condensate management in your paint booth, curing oven, exhaust blowers, ductwork, or pollution control device? The primary reasons for this concern is condensates can affect the quality of your product, affect the indoor air quality of your facility, ruin equipment, create safety concerns, and, lastly, affect your bottom line. Volatile Organic Compound (VOC) based condensation can and will catch on fire, both in your production line and at your pollution control device. That’s something will definitely ruin your day. For all these reasons, you need to be concerned -- very concerned.

Read More

Topics:

Air Pollution Control,

Maintenance and Repairs,

VOC Emissions,

Blog

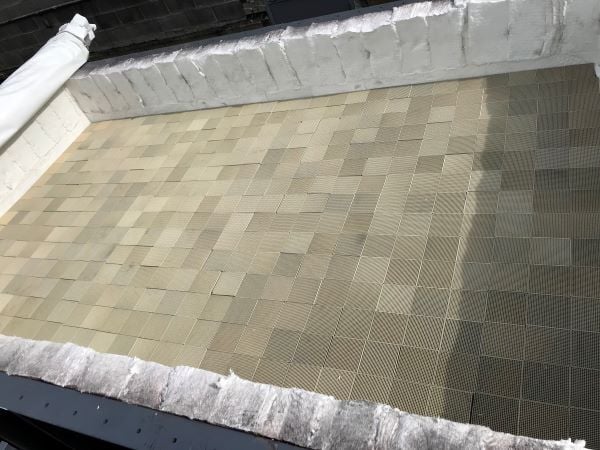

This month, CPI would like to dig deep into the guts of the Regenerative Thermal Oxidizer (RTO) to share an educated understanding of RTO ceramic heat exchange media. In all RTO applications, the selection of the type of media required to best suit your needs is an important decision when buying an RTO, but it could also be an area for improvement in equipment rebuilds. To get started, let’s review the basic types of RTO ceramic heat exchange media:

Read More

Topics:

Air Pollution Control,

Maintenance and Repairs,

Regenerative Thermal Oxidizer,

Blog

Does downtime for your air pollution control system mean a loss of production for your company? If your air pollution control device fails due to a component part failure, does your EPA permit require the plant to shut down operations until the oxidizer is repaired?

Read More

Topics:

Maintenance and Repairs,

Blog

So you’ve reached compliance with your EPA operations permit. Your manufacturing is 100% online. Your team is happy to report that your regenerative thermal oxidizer (RTO) is fully commissioned and running better than expected. These are typical reactions to a Startup/Commissioning sequence on CPI projects. Now that the system is running and production is back to full speed the real question is this: What type of maintenance is required on the RTO? Over the next few months, we’ll be looking at the critical, yet often overlooked, requirements for keeping a quality CPI RTO online and running smoothly.

Read More

Topics:

Maintenance and Repairs,

Regenerative Thermal Oxidizer,

Blog

There are hundreds of types of catalyst products at work in the world today. This series will focus only on the use of precious metal catalysts used in air pollution control systems. The most traditional air pollution control device that employs a precious metal catalyst is a Catalytic Oxidizer. Although catalysts have been used in Regenerative Thermal Oxidizers as a means to lower the operating temperature and reduce natural gas consumption, they can also be installed in a catalytic reactor or catalyst bed where the pollutants are found in a pre-heated exhaust stream.

Read More

Topics:

Air Pollution Control,

Maintenance and Repairs,

Catalytic Oxidizer,

Blog

Accurate measurement of airflow is a key part of properly sizing and selecting a new air pollution control device such as a thermal or catalytic oxidizer. Ongoing maintenance of existing thermal oxidizer’s should also include periodic air flow measurements. Usually, airflow measurement is a straightforward exercise, but special situations sometime occur that require alternatives. In this blog, we'll discuss the basics of airflow measurement and how to handle some problematic conditions.

Read More

Topics:

Air Pollution Control,

Maintenance and Repairs,

Environmental and Regulatory,

Blog

A Regenerative Thermal Oxidizer (RTO) is an air pollution control device that is designed to destroy VOC, HAP, and odorous compounds in order to meet air pollution control regulations. RTOs can be used in small applications (4,000 scfm) to large ones (+100,000 scfm). There are many manufactures of RTOs with a wide variety of media, valves, and overall designs. While there are a lot of differences among the RTOs, one thing is true no matter which system you have installed in your plant: your RTO needs maintenance.

Read More

Topics:

Maintenance and Repairs,

Regenerative Thermal Oxidizer,

Blog

Performing an Energy Assessment

A web coating company contacted us to repair, yet again, an existing recuperative thermal oxidizer. Catalytic Products Design Engineers sat down with the customer to discuss their current process and as well as their future needs along with performing an energy assessment. The outcome of this review indicated that significant savings could be recognized by replacing the Recuperative Thermal Oxidizer with a new Regenerative Thermal Oxidizer (RTO).

Read our case study for more details.

Read More

Topics:

Maintenance and Repairs,

Environmental and Regulatory,

Regenerative Thermal Oxidizer,

Blog,

Rebates

Is it time for a performance audit?

Read More

Topics:

Maintenance and Repairs,

Blog