In our recent blog, "What's the Best Air Pollution Control Technology for My Process?", we examined the many factors that can impact a facility's choice of air pollution control equipment. When they are considering their air pollution control needs, it is important for the plant's engineering staff to discuss the application data with potential suppliers. This data will provide crucial details about the process operation, including as uptime, maximum VOC loading, and maximum air flow. With this data, the supplier will be able to predict energy usage, permitted emission rates, and other process operation data that may be critical to equipment design, and with this knowledge, they will be able to recommend options that meet the requirements for Best Available Control Technology (BACT) or Maximum Available Control Technology (MACT), ensuring that the facility's engineering staff will be able to meet or exceed their environmental goals or outcomes.

Read More

Topics:

Air Pollution Control,

Regenerative Thermal Oxidizer,

Thermal Oxidizer,

Catalytic Oxidizer,

Blog

In our recent blog, "What's the Best Air Pollution Control Technology for My Process?", we took a look at the many factors that inform the choice of air pollution control equipment. When considering air pollution control needs for a facility, it is important for the plant's engineering staff to discuss the application data with potential suppliers. This data includes details about the process operation such as uptime, maximum VOC loading, maximum air flow, energy usage concerns, permitted emission rates, and other process operation data that may be critical to equipment design. Reviewing this data will help determine the available options that will be able to meet or exceed the facility's environmental goals or outcomes. With this data, the air pollution control equipment supplier will then be able to determine the appropriate Best Available Control Technology (BACT) or Maximum Available Control Technology (MACT).

Read More

Topics:

Air Pollution Control,

Regenerative Thermal Oxidizer,

Thermal Oxidizer,

Blog

Internet research and shopping has risen substantially over the past five years, and it will only continue to grow. Searching for a pizza place? Easy. You can customize and define your search by including “Chicago Style,” “Deep Dish,” or maybe “Gluten Free.” This will narrow down the results, helping you find what you asked for. This is a simple process, because you know exactly what you are looking for. You pick a restaurant, order your pizza, and maybe even write a review to help other shoppers find the perfect place to eat. Don’t get me wrong – the internet is fantastic! It is, however, limited to responding to the search terms that we input.

Read More

Topics:

Air Pollution Control,

Regenerative Thermal Oxidizer,

Catalytic Oxidizer,

Blog

At Catalytic Products International, we pride ourselves on helping our clients find cost-effective solutions to their air pollution control needs. With the expertise that we provide, we can make sure their concerns are addressed and that they are happy with the end results. Here on the CPI blog, we’ll be regularly sharing some of our clients’ stories, demonstrating how we’ve helped them find the ideal air pollution control solutions.

Read More

Topics:

Regenerative Thermal Oxidizer,

Chemical Industry,

Customer Testimonials,

Blog,

Heat Recovery

Has your company recently experienced a permit or compliance issue with existing air pollution control equipment? Have you experienced recent growth that is projected to move your emissions above your limits? Do you need help evaluating options for your situation?

Read More

Topics:

Air Pollution Control,

Regenerative Thermal Oxidizer,

Thermal Oxidizer,

Blog

When it comes to air pollution control, understanding the technology that is available is a complicated endeavor, but this knowledge is necessary for complying with environmental regulations. At Catalytic Products International, we are experts in the systems used to control volatile organic compounds (VOCs) and hazardous air pollutants (HAPs), and we want to help you understand how you can use these oxidizers for VOC control and to meet all your air pollution control needs.

There are 5 basic, distinct types of oxidizers used for VOC control. Let's look at each of them, along with some simple guidelines to point you in direction of the correct oxidizer for your process.

Read More

Topics:

Air Pollution Control,

Regenerative Thermal Oxidizer,

Thermal Oxidizer,

Catalytic Oxidizer,

Blog

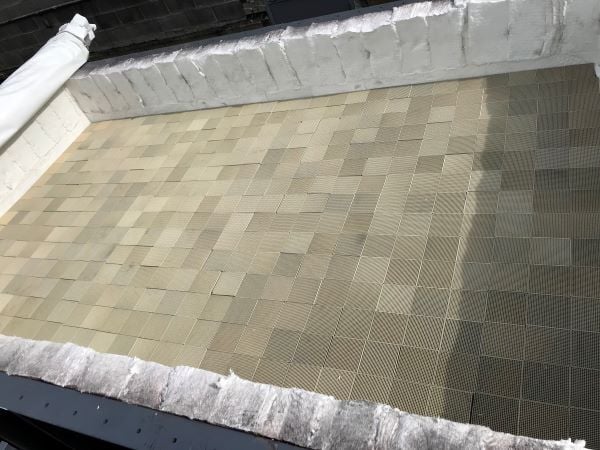

This month, CPI would like to dig deep into the guts of the Regenerative Thermal Oxidizer (RTO) to share an educated understanding of RTO ceramic heat exchange media. In all RTO applications, the selection of the type of media required to best suit your needs is an important decision when buying an RTO, but it could also be an area for improvement in equipment rebuilds. To get started, let’s review the basic types of RTO ceramic heat exchange media:

Read More

Topics:

Air Pollution Control,

Maintenance and Repairs,

Regenerative Thermal Oxidizer,

Blog

At Catalytic Products International, we work with our clients every day to help them ensure that they are addressing their air pollution control needs as efficiently and cost-effectively as possible. With our years of experience and level of expertise, we can help them address their concerns and find the best solutions to meet their needs. Each client we work with is different, and we want to share their stories to show how CPI can provide the best air pollution control solutions for any industry.

Read More

Topics:

Regenerative Thermal Oxidizer,

Customer Testimonials,

Flexographic Printing,

Blog,

Installation,

Rebates

So you’ve reached compliance with your EPA operations permit. Your manufacturing is 100% online. Your team is happy to report that your regenerative thermal oxidizer (RTO) is fully commissioned and running better than expected. These are typical reactions to a Startup/Commissioning sequence on CPI projects. Now that the system is running and production is back to full speed the real question is this: What type of maintenance is required on the RTO? Over the next few months, we’ll be looking at the critical, yet often overlooked, requirements for keeping a quality CPI RTO online and running smoothly.

Read More

Topics:

Maintenance and Repairs,

Regenerative Thermal Oxidizer,

Blog

A Regenerative Thermal Oxidizer (RTO) is an air pollution control device that is designed to destroy VOC, HAP, and odorous compounds in order to meet air pollution control regulations. RTOs can be used in small applications (4,000 scfm) to large ones (+100,000 scfm). There are many manufactures of RTOs with a wide variety of media, valves, and overall designs. While there are a lot of differences among the RTOs, one thing is true no matter which system you have installed in your plant: your RTO needs maintenance.

Read More

Topics:

Maintenance and Repairs,

Regenerative Thermal Oxidizer,

Blog