Selective Catalytic Reduction (SCR) is a term used in the air pollution control industry for the process of selectively targeting a pollutant to remove that pollutant from an exhaust stream. The most common pollutant that is controlled through a SCR process is nitrogen oxide (NOx). While there are many catalysts that can selectively target a number of compounds, the content of this blog will focus on SCR technologies for the reduction of NOx.

Read More

Topics:

Air Pollution Control,

Catalytic Oxidizer,

Blog,

SCR

Any facility operator that consumes significant amounts of natural gas should understand the basics of heat recovery. Here at Catalytic Products International (CPI), we find ourselves engaged in energy conservation discussions with our existing and prospective customers several times each week. We felt that “Heat Recovery 101” may be a useful tool to help our readers fully understand some of the basics and economics about heat recovery solutions.

Read More

Topics:

Air Pollution Control,

Waste Heat Recovery,

Blog

There are hundreds of types of catalyst products at work in the world today. This series will focus only on the use of precious metal catalysts used in air pollution control systems. The most traditional air pollution control device that employs a precious metal catalyst is a Catalytic Oxidizer. Although catalysts have been used in Regenerative Thermal Oxidizers as a means to lower the operating temperature and reduce natural gas consumption, they can also be installed in a catalytic reactor or catalyst bed where the pollutants are found in a pre-heated exhaust stream.

Read More

Topics:

Air Pollution Control,

Maintenance and Repairs,

Catalytic Oxidizer,

Blog

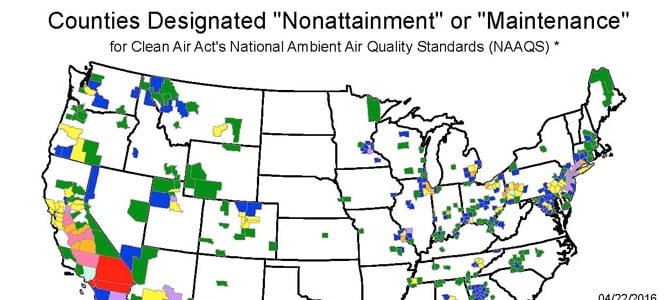

As the U.S. Environmental Protection Agency (EPA) develops new control technique guidelines, the definition of the RACT (Reasonably Available Control Technology) standards changes on a state level.

Read More

Topics:

Environmental and Regulatory,

Blog

Accurate measurement of airflow is a key part of properly sizing and selecting a new air pollution control device such as a thermal or catalytic oxidizer. Ongoing maintenance of existing thermal oxidizer’s should also include periodic air flow measurements. Usually, airflow measurement is a straightforward exercise, but special situations sometime occur that require alternatives. In this blog, we'll discuss the basics of airflow measurement and how to handle some problematic conditions.

Read More

Topics:

Air Pollution Control,

Maintenance and Repairs,

Environmental and Regulatory,

Blog

Air quality regulation starts with National Ambient Air Quality Standards, more commonly known by the abbreviation NAAQS. The NAAQS represent the maximum concentration of each regulated pollutant that can be present in the air we breathe, according to the Environmental Protection Agency (EPA). Each maximum concentration is chosen to fulfill the EPA’s mandate to protect human health and the environment.

Read More

Topics:

Air Pollution Control,

Environmental and Regulatory,

Blog

Recently, the National Fire Protection Association (NFPA) funded a report that looks to gather information regarding explosions in ovens, furnaces, and dryers. The report was prepared by Sreenivasan Ranganathan and Sean Gillis of the Fire Protection Research Foundation. The report is important work that will be used by the NFPA technical committee during review of the upcoming code revisions.

Recently, the National Fire Protection Association (NFPA) funded a report that looks to gather information regarding explosions in ovens, furnaces, and dryers. The report was prepared by Sreenivasan Ranganathan and Sean Gillis of the Fire Protection Research Foundation. The report is important work that will be used by the NFPA technical committee during review of the upcoming code revisions.

Read More

Topics:

Environmental and Regulatory,

Safety Regulations,

Blog

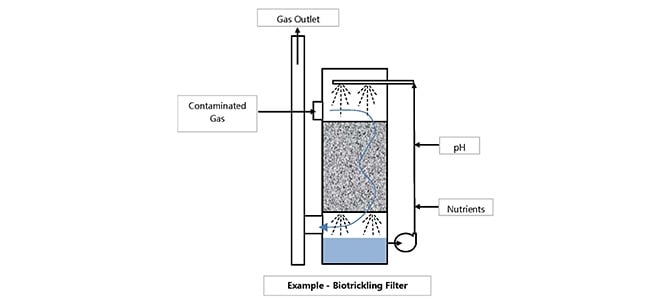

Many pollutants, both natural and synthetic, are gaseous in nature and require specific technology to effectively remove the pollutant from an exhaust or process gas stream. Gaseous industrial pollutants can include:

Read More

Topics:

Air Pollution Control,

Environmental and Regulatory,

Blog

A Regenerative Thermal Oxidizer (RTO) is an air pollution control device that is designed to destroy VOC, HAP, and odorous compounds in order to meet air pollution control regulations. RTOs can be used in small applications (4,000 scfm) to large ones (+100,000 scfm). There are many manufactures of RTOs with a wide variety of media, valves, and overall designs. While there are a lot of differences among the RTOs, one thing is true no matter which system you have installed in your plant: your RTO needs maintenance.

Read More

Topics:

Maintenance and Repairs,

Regenerative Thermal Oxidizer,

Blog

One question which we frequently receive is about the length of the process of building and installing an oxidizer. There are many factors which influence the oxidizer installation process, including the client’s procurement process and the complexity of the equipment and location of the site. In this series of blogs, we’ve been taking a look at a typical industrial process utilizing a standard thermal oxidizer, catalytic oxidizer, or regenerative thermal oxidizer. We’ve previously discussed the timelines for the client buying process and oxidizer delivery and installation. In this final blog, we’ll look at the timeline for compliance testing.

One question which we frequently receive is about the length of the process of building and installing an oxidizer. There are many factors which influence the oxidizer installation process, including the client’s procurement process and the complexity of the equipment and location of the site. In this series of blogs, we’ve been taking a look at a typical industrial process utilizing a standard thermal oxidizer, catalytic oxidizer, or regenerative thermal oxidizer. We’ve previously discussed the timelines for the client buying process and oxidizer delivery and installation. In this final blog, we’ll look at the timeline for compliance testing.

Read More

Topics:

Air Pollution Control,

VOC Emissions,

Regenerative Thermal Oxidizer,

Thermal Oxidizer,

Blog,

Installation,

DRE Test

Recently, the National Fire Protection Association (NFPA) funded a report that looks to gather information regarding explosions in ovens, furnaces, and dryers. The report was prepared by Sreenivasan Ranganathan and Sean Gillis of the Fire Protection Research Foundation. The report is important work that will be used by the NFPA technical committee during review of the upcoming code revisions.

Recently, the National Fire Protection Association (NFPA) funded a report that looks to gather information regarding explosions in ovens, furnaces, and dryers. The report was prepared by Sreenivasan Ranganathan and Sean Gillis of the Fire Protection Research Foundation. The report is important work that will be used by the NFPA technical committee during review of the upcoming code revisions.

One question which we frequently receive is about the length of the process of building and installing an oxidizer. There are many factors which influence the oxidizer installation process, including the client’s procurement process and the complexity of the equipment and location of the site. In this series of blogs, we’ve been taking a look at a typical industrial process utilizing a standard thermal oxidizer, catalytic oxidizer, or regenerative thermal oxidizer. We’ve previously discussed the timelines for

One question which we frequently receive is about the length of the process of building and installing an oxidizer. There are many factors which influence the oxidizer installation process, including the client’s procurement process and the complexity of the equipment and location of the site. In this series of blogs, we’ve been taking a look at a typical industrial process utilizing a standard thermal oxidizer, catalytic oxidizer, or regenerative thermal oxidizer. We’ve previously discussed the timelines for