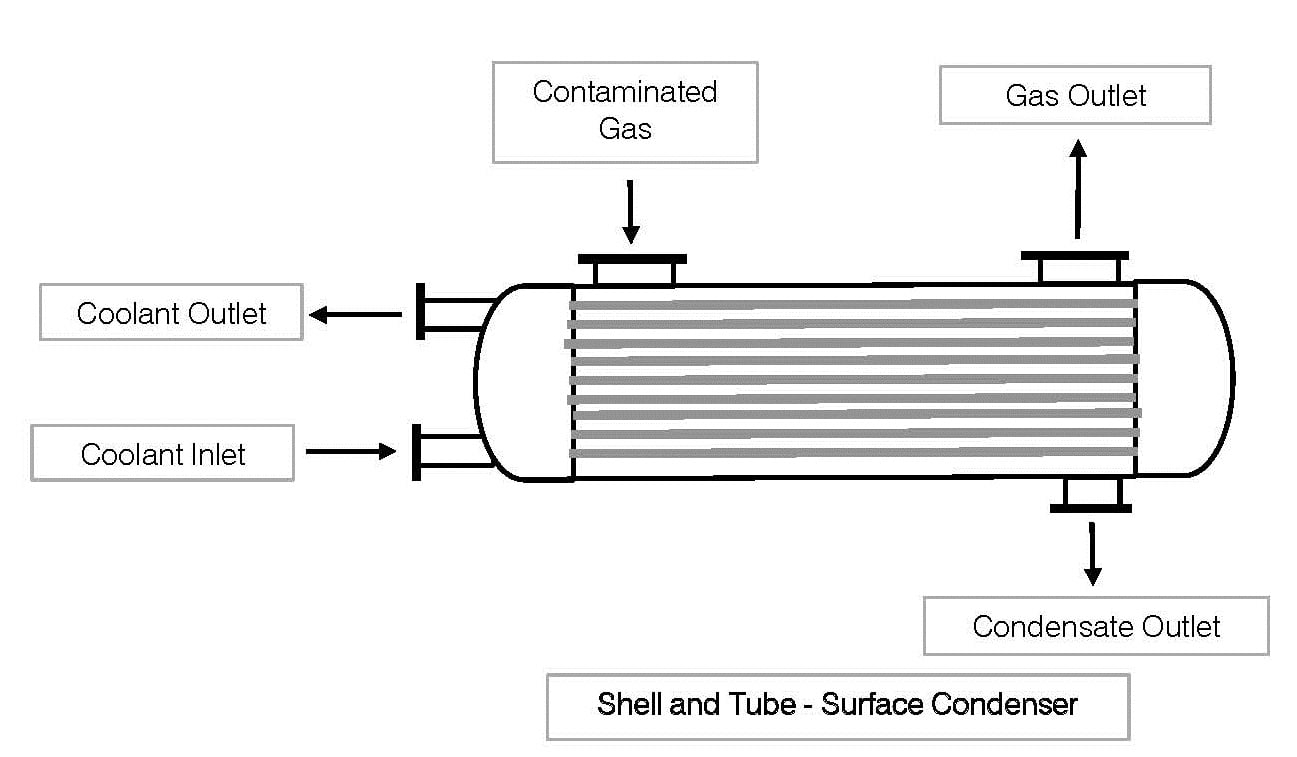

Many pollutants, both natural and synthetic, are gaseous in nature and require specific technology to effectively remove the pollutant from an exhaust or process gas stream. Gaseous industrial pollutants can include:

Read More

Topics:

Air Pollution Control,

Environmental and Regulatory,

Blog

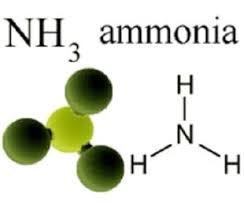

Ammonia (NH3) is one of the most commonly produced industrial chemicals in the United States. It is used in industry and commerce, and it also exists naturally in humans and in the environment. Ammonia is essential for many biological processes and serves as a precursor for amino acid and nucleotide synthesis. In the environment, ammonia is part of the nitrogen cycle and is produced in soil from bacterial processes. Ammonia is also produced naturally from decomposition of organic matter, including plants, animals, and animal wastes.

Read More

Topics:

Air Pollution Control,

Environmental and Regulatory,

Blog,

Ammonia

Air pollution control is a complicated subject, but it is incredibly important for any company that uses industrial processes to understand how to manage the volatile organic compounds (VOCs) and hazardous air pollutants (HAPs) that they produce. But before companies proceed with planning and budgeting for an air pollution control device, there are several questions they need to answer:

Air pollution control is a complicated subject, but it is incredibly important for any company that uses industrial processes to understand how to manage the volatile organic compounds (VOCs) and hazardous air pollutants (HAPs) that they produce. But before companies proceed with planning and budgeting for an air pollution control device, there are several questions they need to answer:

Read More

Topics:

Air Pollution Control,

Thermal Oxidizer,

Blog

At CPI, we are frequently asked about the length of time necessary to build and install an oxidizer. The answer to that question is complicated, depending on a variety of factors such as the client’s procurement process and the complexity of the equipment and location of the site. To help build understanding of the decisions that go into this process, we wanted to take a closer look at a typical industrial process utilizing a standard thermal oxidizer, catalytic oxidizer, or regenerative thermal oxidizer. In our first blog on this topic, we looked at the client buying process. Today, we’ll look at the timeline for oxidizer deliver and installation.

At CPI, we are frequently asked about the length of time necessary to build and install an oxidizer. The answer to that question is complicated, depending on a variety of factors such as the client’s procurement process and the complexity of the equipment and location of the site. To help build understanding of the decisions that go into this process, we wanted to take a closer look at a typical industrial process utilizing a standard thermal oxidizer, catalytic oxidizer, or regenerative thermal oxidizer. In our first blog on this topic, we looked at the client buying process. Today, we’ll look at the timeline for oxidizer deliver and installation.

Read More

Topics:

Air Pollution Control,

VOC Emissions,

Regenerative Thermal Oxidizer,

Thermal Oxidizer,

Blog,

Installation

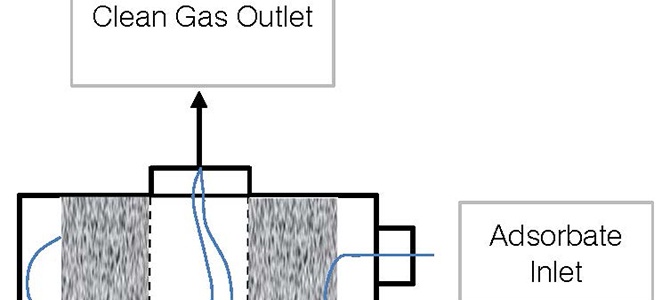

Many pollutants, both natural and synthetic, are gaseous in nature and require specific technology to effectively remove the pollutant from an exhaust or process gas stream. Gaseous industrial pollutants can include:

Read More

Topics:

Air Pollution Control,

Environmental and Regulatory,

Blog,

Activated Carbon

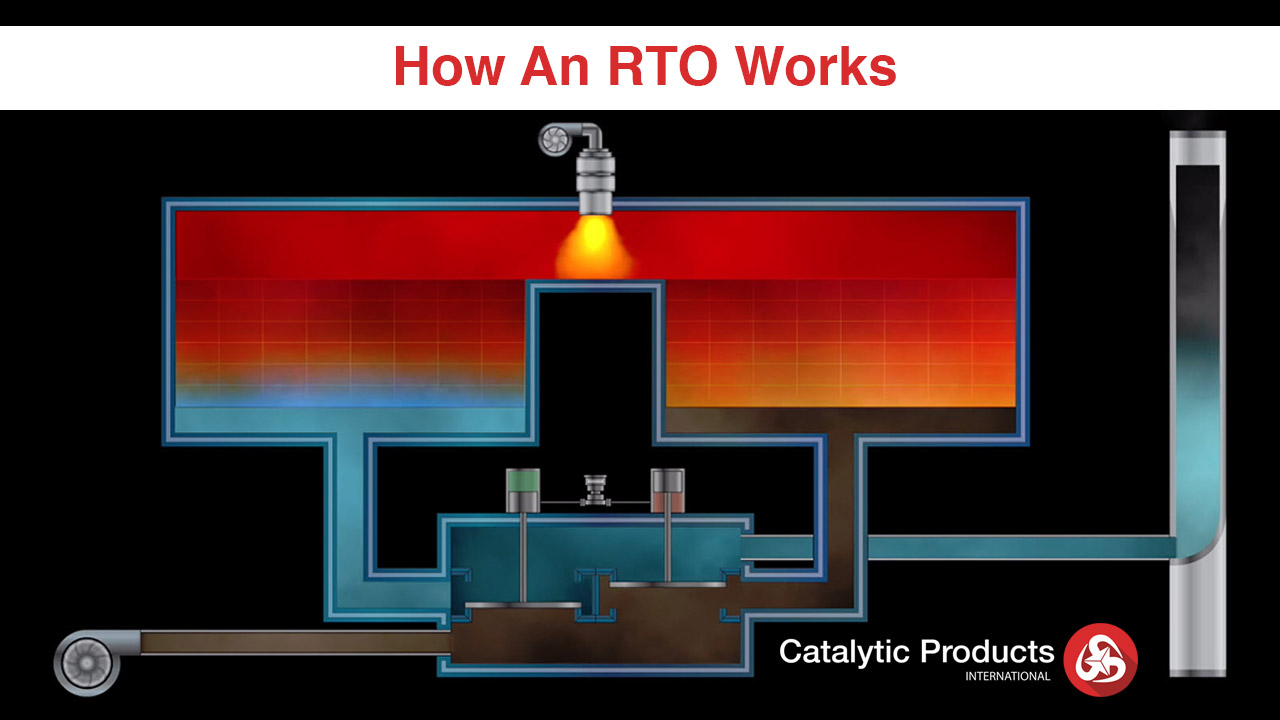

In our previous post we discussed what air pollution is and why anyone may need a Regenerative Thermal Oxidizer (RTO). In this post we explore more details about various RTO designs and describe the operating principles.

Read More

Topics:

Air Pollution Control,

Environmental and Regulatory,

Regenerative Thermal Oxidizer,

Blog

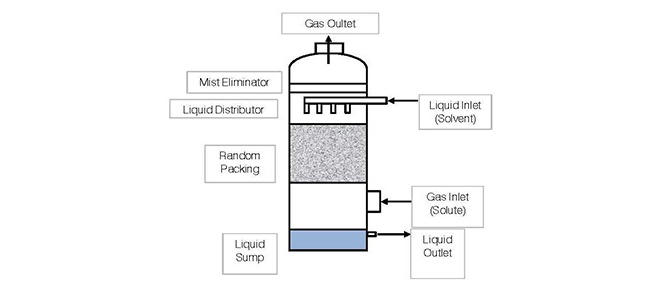

Many pollutants, both natural and synthetic, are gaseous in nature and require specific technology to effectively remove the pollutant from an exhaust or process gas stream. Gaseous industrial pollutants can include:

Read More

Topics:

Air Pollution Control,

Environmental and Regulatory,

Blog,

Acid Gas Scrubber

Our first encounters with our customers often start with this statement; “I was told that I need a RTO.” That’s obviously a big statement which usually leads to many more questions to precisely determine where we can help. This also means that the person with interest has some sort of air pollution control problem that may involve volatile organic compounds (VOC), carbon monoxide (CO) or odorous emissions.

It may be helpful to understand the basic reason anyone would need a

Regenerative Thermal Oxidizer (RTO).

Read More

Topics:

Air Pollution Control,

Environmental and Regulatory,

Regenerative Thermal Oxidizer,

Blog

If you haven’t had a Title V permit, but one may be in your future, you may wonder what’s in store. In this post, we’ll take a look at the Title V permit program, which has been a feature of environmental regulation in the United States for over twenty years.

Read More

Topics:

Air Pollution Control,

VOC Emissions,

Environmental and Regulatory,

Regenerative Thermal Oxidizer,

Thermal Oxidizer,

Blog

One of our most frequently asked questions is, “How long does it take to build an oxidizer?” The answer depends on the client’s procurement process as well as the complexity of the equipment and location of the site. This series of blogs will focus on a typical industrial process utilizing a standard thermal oxidizer, catalytic oxidizer, or regenerative thermal oxidizer. Since this is a complicated topic, we wanted to separate it out into a few steps. In this first blog, we’ll look at the client buying process.

One of our most frequently asked questions is, “How long does it take to build an oxidizer?” The answer depends on the client’s procurement process as well as the complexity of the equipment and location of the site. This series of blogs will focus on a typical industrial process utilizing a standard thermal oxidizer, catalytic oxidizer, or regenerative thermal oxidizer. Since this is a complicated topic, we wanted to separate it out into a few steps. In this first blog, we’ll look at the client buying process.

Read More

Topics:

Air Pollution Control,

VOC Emissions,

Regenerative Thermal Oxidizer,

Thermal Oxidizer,

Blog

Air pollution control is a complicated subject, but it is incredibly important for any company that uses industrial processes to understand how to manage the volatile organic compounds (VOCs) and hazardous air pollutants (HAPs) that they produce. But before companies proceed with planning and budgeting for an air pollution control device, there are several questions they need to answer:

Air pollution control is a complicated subject, but it is incredibly important for any company that uses industrial processes to understand how to manage the volatile organic compounds (VOCs) and hazardous air pollutants (HAPs) that they produce. But before companies proceed with planning and budgeting for an air pollution control device, there are several questions they need to answer:

At CPI, we are frequently asked about the length of time necessary to build and install an oxidizer. The answer to that question is complicated, depending on a variety of factors such as the client’s procurement process and the complexity of the equipment and location of the site. To help build understanding of the decisions that go into this process, we wanted to take a closer look at a typical industrial process utilizing a standard thermal oxidizer, catalytic oxidizer, or regenerative thermal oxidizer. In our first blog on this topic, we looked at

At CPI, we are frequently asked about the length of time necessary to build and install an oxidizer. The answer to that question is complicated, depending on a variety of factors such as the client’s procurement process and the complexity of the equipment and location of the site. To help build understanding of the decisions that go into this process, we wanted to take a closer look at a typical industrial process utilizing a standard thermal oxidizer, catalytic oxidizer, or regenerative thermal oxidizer. In our first blog on this topic, we looked at